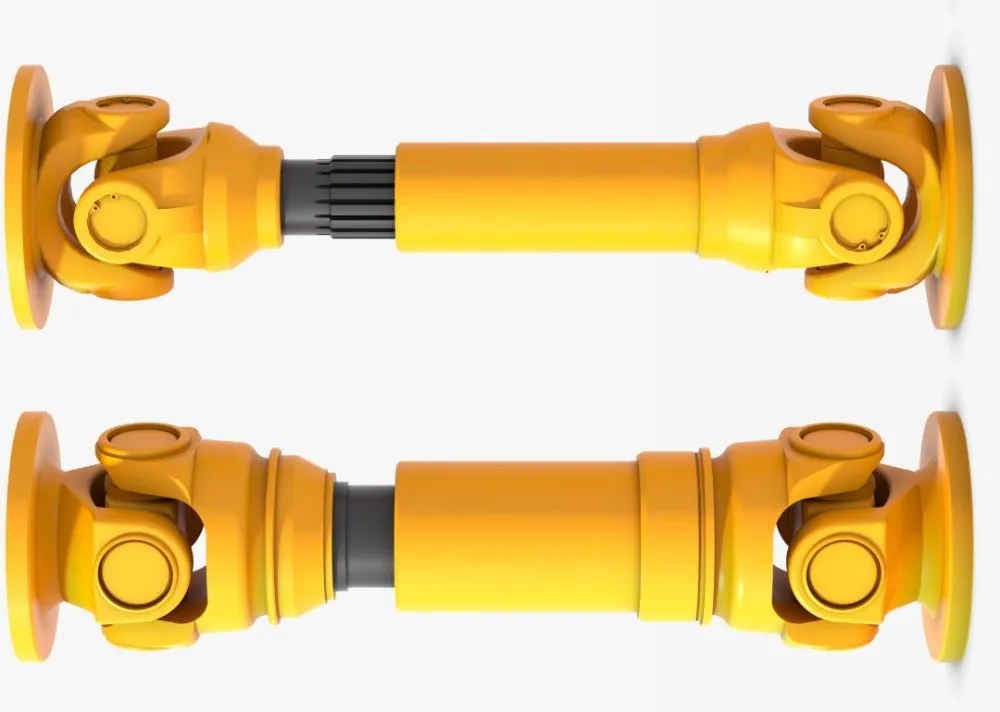

Product Description

Features

1.Many sizes available

2.Max. angle 45 degree

3.Max. speed 1000 rpm

4.Available in various materials

5.All subcomponents very precisely machined from bar: No cheap castings or powdered metal parts, resulting in better overall and more consistent performance

6.Several subtle design innovations that optimize performance and reduce cost

7.Could manufacture products according to your drawing

Advantages

1.Application to all kinds of general mechanical situation, maximum rotate speed may reach1000~1500r/min.Our Universal Joint widely used in multiaxle drilling machine ,construction machine,packaging machine,automobile.parking facility and paper machine,medical machine,farm machine.

2.Have single -jointed type and bimodal type.

3.Each point of the largest rotation angle can be 45o.

4.Needle roller bearing,maintenance-free.

5.The hole on the finshed product tolerance is H7 according to spline , hexagonal and square hole are available as long as you request.

Variations offered

1.Materials for midsection(Cube and Pin): 20Cr,40Cr

2.Materials for hub: 40Cr,45#steel

3. Materials for spline: 45#steel

4.Quick-Change universal joint(Nature color)

| Packing&Shipping | |

| Package | Standard suitable package / Pallet or container. Polybag inside export carton outside, blister and Tape and reel package available. If customers have specific requirements for the packaging, we will gladly accommodate. |

| Shipping | 10-20working days ofter payment receipt comfirmed (based on actual quantity). Packing standard export packing or according to customers demand. Professional goods shipping forward. |

About MIGHTY

ZheJiang Mighty Machinery Co., Ltd. specializes in manufacturing Mechanical Power Transmission Products.We Mighty is the division/branch of SCMC Group, which is a wholly state-owned company, established in 1980.

About Mighty:

-3 manufacturing factories, we have 5 technical staff, our FTY have strong capacity for design and process design, and more than 70 workers and double shift eveyday.

-Large quality of various material purchase and stock in warhouse which ensure the low cost for the material and production in time.

-Strick quality control are apply in the whole production.

we have incoming inspection,process inspection and final production inspection which can ensure the perfect of the goods quality.

-14 years of machining experience. Long time cooperate with the Global Buyer, make us easy to understand the csutomer and handle the export. MIGHTY’s products are mainly exported to Europe, America and the Middle East market. With the top-ranking management, professional technical support and abundant export experience, MIGHTY has established lasting and stable business partnership with many world famous companies and has got good reputation from CHINAMFG customers in international sales.

FAQ

Q: Are you trading company or manufacturer?

A: We are factory.

Q: How long is your delivery time?

A: Generally it is 5-10 days if the goods are in stock. or it is 15-20 days if the goods are not in stock, it is according to quantity.

Q: Do you provide samples ? is it free or extra ?

A: Yes, we could offer the sample for free charge but do not pay the cost of freight.

Q: What is your terms of payment ?

A: Payment=1000USD, 30% T/T in advance ,balance before shippment.

We warmly welcome friends from domestic and abroad come to us for business negotiation and cooperation for mutual benefit. To supply customers excellent quality products with good price and punctual delivery time is our responsibility. /* March 10, 2571 17:59:20 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| After-sales Service: | Technical Support |

|---|---|

| Warranty: | 1 Year |

| Condition: | New |

| Color: | Natural Color, Silver, Black |

| Certification: | CE, DIN, ISO |

| Structure: | Single or Double |

| Samples: |

US$ 0/Piece

1 Piece(Min.Order) | |

|---|

| Customization: |

Available

| Customized Request |

|---|

How do you calculate the operating angles of a cardan joint?

The operating angles of a cardan joint can be calculated based on the angular misalignment between the input and output shafts. The operating angles are crucial for determining the joint’s performance and ensuring its proper functioning. Here’s a detailed explanation of how to calculate the operating angles of a cardan joint:

- Identify the Shaft Axes: Begin by identifying the axes of the input and output shafts connected by the cardan joint. These axes represent the rotational axes of the shafts.

- Measure the Angular Misalignments: Measure the angular misalignments between the shaft axes. The misalignments are typically measured in terms of angles, such as angular displacement in degrees or radians. There are three types of misalignments to consider:

- Angular Misalignment (α): This refers to the angular difference between the two shaft axes in the horizontal plane (X-Y plane).

- Parallel Misalignment (β): Parallel misalignment represents the offset or displacement between the two shaft axes in the vertical plane (Z-axis).

- Axial Misalignment (γ): Axial misalignment refers to the shift or displacement of one shaft along its axis with respect to the other shaft.

- Calculate the Operating Angles: Once the misalignments are measured, the operating angles can be calculated using trigonometric functions. The operating angles are:

- Operating Angle (θ): The operating angle is the total angular misalignment between the input and output shafts. It is calculated as the square root of the sum of the squares of the individual misalignments:

These calculated operating angles provide valuable information about the misalignment and geometry of the cardan joint. They help in selecting the appropriate joint size, determining the joint’s torque capacity, assessing potential operating issues, and ensuring proper installation and alignment of the joint within the system.

It is important to note that these calculations assume small operating angles and neglect any elastic deformation or non-linearities that may occur in the joint. In cases where larger operating angles or more precise calculations are required, advanced engineering techniques or software tools specific to cardan joint analysis may be employed.

What are the safety considerations when working with cardan joints?

Working with cardan joints requires careful attention to safety to prevent accidents, injuries, and equipment damage. Cardan joints are mechanical components used for torque transmission and misalignment compensation, and they operate under various loads and conditions. Here are important safety considerations to keep in mind when working with cardan joints:

- Proper Training and Knowledge: Ensure that individuals working with cardan joints have proper training and understanding of their operation, installation, and maintenance. Adequate knowledge of safe working practices, procedures, and potential hazards associated with cardan joints is crucial.

- Personal Protective Equipment (PPE): Use appropriate personal protective equipment, such as safety glasses, gloves, and protective clothing, when handling cardan joints. PPE protects against potential hazards like flying debris, sharp edges, or accidental contact with rotating components.

- Lockout/Tagout: Before performing any maintenance or repair work involving cardan joints, follow lockout/tagout procedures to isolate and de-energize the system. This prevents accidental startup or movement of machinery, ensuring the safety of personnel working on or near the cardan joints.

- Secure Mounting and Fastening: Ensure that cardan joints are securely mounted and properly fastened to prevent unexpected movement or dislodgment during operation. Loose joints or fasteners can lead to component failure, sudden movements, or damage to other parts of the system.

- Torque and Load Limits: Adhere to the recommended torque and load limits specified by the manufacturer for the cardan joints. Exceeding these limits can result in premature wear, deformation, or failure of the joints, posing safety risks and compromising the overall system’s functionality.

- Regular Inspection and Maintenance: Implement a regular inspection and maintenance program for the cardan joints. Inspect for signs of wear, damage, or misalignment, and address any issues promptly. Lubricate the joints according to the manufacturer’s recommendations to ensure smooth operation and prevent excessive friction or overheating.

- Safe Handling and Lifting: When handling or lifting cardan joints, use appropriate lifting equipment and techniques. Cardan joints can be heavy, and improper lifting can lead to strain or injuries. Ensure that lifting devices have the capacity to handle the weight of the joints safely.

- Avoid Contact with Rotating Components: Never reach into or make contact with rotating components of a system that incorporates cardan joints while the system is in operation. Keep loose clothing, jewelry, and other items away from moving parts to prevent entanglement or injury.

- Proper Disposal of Used or Damaged Joints: Follow proper disposal procedures for used or damaged cardan joints. Consult local regulations and guidelines for the disposal of mechanical components to minimize environmental impact and ensure compliance with safety and waste management standards.

- Manufacturer’s Guidelines: Always refer to and follow the manufacturer’s guidelines, instructions, and warnings specific to the cardan joints being used. Manufacturers provide important safety information, installation procedures, and maintenance recommendations specific to their products.

By addressing these safety considerations, individuals can mitigate potential risks associated with working with cardan joints, promote a safe working environment, and ensure the reliable and efficient operation of the systems they are integrated into.

What is a cardan joint and how does it work?

A cardan joint, also known as a universal joint or U-joint, is a mechanical coupling used to transmit rotational motion between two shafts that are not collinear or have a constant angular relationship. It provides flexibility and accommodates misalignment between the shafts. Here’s a detailed explanation of how a cardan joint works:

A cardan joint consists of three main components: two yokes and a cross-shaped member called the cross or spider. The yokes are attached to the ends of the shafts that need to be connected, while the cross sits in the center, connecting the yokes.

The cross has four arms that intersect at a central point, forming a cross shape. Each arm has a bearing surface or trunnion on which the yoke of the corresponding shaft is mounted. The yokes are typically fork-shaped and have holes or bearings to accommodate the trunnions of the cross.

When the input shaft rotates, it transfers the rotational motion to one of the yokes. The cross, being connected to both yokes, transmits this motion to the other yoke and subsequently to the output shaft.

The key feature of a cardan joint is its ability to accommodate misalignment between the input and output shafts. This misalignment can be angular, axial, or both. As the input and output shafts are not collinear, the angles between the shafts cause the yokes to rotate at different speeds during operation.

The universal joint’s design allows the cross to rotate freely within the yokes, while still transferring motion from one shaft to the other. When the input shaft rotates, the yoke connected to it rotates with the shaft. This rotation causes the cross to tilt, as the other yoke is fixed to the output shaft. As a result, the angle between the arms of the cross changes, allowing for the compensation of misalignment.

As the cross tilts, the relative speeds of the yokes change, but the rotational motion is still transferred to the output shaft. The cardan joint effectively converts the input shaft’s rotation into a modified rotation at the output shaft, accommodating the misalignment between the two shafts.

It’s important to note that while cardan joints provide flexibility and can handle misalignment, they introduce certain limitations. These include non-uniform motion, increased vibration, backlash, and potential loss of efficiency at extreme operating angles. Regular maintenance, proper lubrication, and adherence to manufacturer guidelines are essential to ensure the optimal performance and longevity of cardan joints.

editor by CX 2024-01-25

China manufacturer Agriculture Machinery Parts Cardan Transmission Tractor Parts Pto Drive Shaft Practical Drive Shaft with CE Certificate OEM ODM with Best Sales

Product Description

Agriculture Machinery parts Cardan Transmission Tractor Parts Pto Drive Shaft Practical Drive Shaft with CE Certificate OEM ODM

Power Take Off Shafts for all applications

A power take-off or power takeoff (PTO) is any of several methods for taking power from a power source, such as a running engine, and transmitting it to an application such as an attached implement or separate machines.

Most commonly, it is a splined drive shaft installed on a tractor or truck allowing implements with mating fittings to be powered directly by the engine.

Semi-permanently mounted power take-offs can also be found on industrial and marine engines. These applications typically use a drive shaft and bolted joint to transmit power to a secondary implement or accessory. In the case of a marine application, such shafts may be used to power fire pumps.

We offer high-quality PTO shaft parts and accessories, including clutches, tubes, and yokes for your tractor and implements, including an extensive range of pto driveline. Request our pto shaft products at the best rate possible.

What does a power take off do?

Power take-off (PTO) is a device that transfers an engine’s mechanical power to another piece of equipment. A PTO allows the hosting energy source to transmit power to additional equipment that does not have its own engine or motor. For example, a PTO helps to run a jackhammer using a tractor engine.

What’s the difference between 540 and 1000 PTO?

When a PTO shaft is turning 540, the ratio must be adjusted (geared up or down) to meet the needs of the implement, which is usually higher RPM’s than that. Since 1000 RPM’s is almost double that of 540, there is less “”Gearing Up”” designed in the implement to do the job required.”

If you are looking for a PTO speed reducer visit here

| Function | Power transmission |

| Use | Tractors and various farm implements |

| Place of Origin | HangZhou ,ZHangZhoug, China (Mainland) |

| Brand Name | EPT |

| Yoke Type | push pin/quick release/collar/double push pin/bolt pins/split pins |

| Processing Of Yoke | Forging |

| Plastic Cover | YW;BW;YS;BS |

| Color | Yellow;black |

| Series | T series; L series; S series |

| Tube Type | Trianglar/star/lemon |

| Processing Of Tube | Cold drawn |

| Spline Type | 1 3/8″ Z6; 1 3/8 Z21 ;1 3/4 Z20;1 1/8 Z6; 1 3/4 Z6; |

Related Products

Application:

Company information:

Worm Gear Motors

Worm gear motors are often preferred for quieter operation because of the smooth sliding motion of the worm shaft. Unlike gear motors with teeth, which may click as the worm turns, worm gear motors can be installed in a quiet area. In this article, we will talk about the CZPT whirling process and the various types of worms available. We’ll also discuss the benefits of worm gear motors and worm wheel.

worm gear

In the case of a worm gear, the axial pitch of the ring pinion of the corresponding revolving worm is equal to the circular pitch of the mating revolving pinion of the worm gear. A worm with 1 start is known as a worm with a lead. This leads to a smaller worm wheel. Worms can work in tight spaces because of their small profile.

Generally, a worm gear has high efficiency, but there are a few disadvantages. Worm gears are not recommended for high-heat applications because of their high level of rubbing. A full-fluid lubricant film and the low wear level of the gear reduce friction and wear. Worm gears also have a lower wear rate than a standard gear. The worm shaft and worm gear is also more efficient than a standard gear.

The worm gear shaft is cradled within a self-aligning bearing block that is attached to the gearbox casing. The eccentric housing has radial bearings on both ends, enabling it to engage with the worm gear wheel. The drive is transferred to the worm gear shaft through bevel gears 13A, 1 fixed at the ends of the worm gear shaft and the other in the center of the cross-shaft.

worm wheel

In a worm gearbox, the pinion or worm gear is centered between a geared cylinder and a worm shaft. The worm gear shaft is supported at either end by a radial thrust bearing. A gearbox’s cross-shaft is fixed to a suitable drive means and pivotally attached to the worm wheel. The input drive is transferred to the worm gear shaft 10 through bevel gears 13A, 1 of which is fixed to the end of the worm gear shaft and the other at the centre of the cross-shaft.

Worms and worm wheels are available in several materials. The worm wheel is made of bronze alloy, aluminum, or steel. Aluminum bronze worm wheels are a good choice for high-speed applications. Cast iron worm wheels are cheap and suitable for light loads. MC nylon worm wheels are highly wear-resistant and machinable. Aluminum bronze worm wheels are available and are good for applications with severe wear conditions.

When designing a worm wheel, it is vital to determine the correct lubricant for the worm shaft and a corresponding worm wheel. A suitable lubricant should have a kinematic viscosity of 300 mm2/s and be used for worm wheel sleeve bearings. The worm wheel and worm shaft should be properly lubricated to ensure their longevity.

Multi-start worms

A multi-start worm gear screw jack combines the benefits of multiple starts with linear output speeds. The multi-start worm shaft reduces the effects of single start worms and large ratio gears. Both types of worm gears have a reversible worm that can be reversed or stopped by hand, depending on the application. The worm gear’s self-locking ability depends on the lead angle, pressure angle, and friction coefficient.

A single-start worm has a single thread running the length of its shaft. The worm advances 1 tooth per revolution. A multi-start worm has multiple threads in each of its threads. The gear reduction on a multi-start worm is equal to the number of teeth on the gear minus the number of starts on the worm shaft. In general, a multi-start worm has 2 or 3 threads.

Worm gears can be quieter than other types of gears because the worm shaft glides rather than clicking. This makes them an excellent choice for applications where noise is a concern. Worm gears can be made of softer material, making them more noise-tolerant. In addition, they can withstand shock loads. Compared to gears with toothed teeth, worm gears have a lower noise and vibration rate.

CZPT whirling process

The CZPT whirling process for worm shafts raises the bar for precision gear machining in small to medium production volumes. The CZPT whirling process reduces thread rolling, increases worm quality, and offers reduced cycle times. The CZPT LWN-90 whirling machine features a steel bed, programmable force tailstock, and five-axis interpolation for increased accuracy and quality.

Its 4,000-rpm, 5-kW whirling spindle produces worms and various types of screws. Its outer diameters are up to 2.5 inches, while its length is up to 20 inches. Its dry-cutting process uses a vortex tube to deliver chilled compressed air to the cutting point. Oil is also added to the mixture. The worm shafts produced are free of undercuts, reducing the amount of machining required.

Induction hardening is a process that takes advantage of the whirling process. The induction hardening process utilizes alternating current (AC) to cause eddy currents in metallic objects. The higher the frequency, the higher the surface temperature. The electrical frequency is monitored through sensors to prevent overheating. Induction heating is programmable so that only certain parts of the worm shaft will harden.

Common tangent at an arbitrary point on both surfaces of the worm wheel

A worm gear consists of 2 helical segments with a helix angle equal to 90 degrees. This shape allows the worm to rotate with more than 1 tooth per rotation. A worm’s helix angle is usually close to 90 degrees and the body length is fairly long in the axial direction. A worm gear with a lead angle g has similar properties as a screw gear with a helix angle of 90 degrees.

The axial cross section of a worm gear is not conventionally trapezoidal. Instead, the linear part of the oblique side is replaced by cycloid curves. These curves have a common tangent near the pitch line. The worm wheel is then formed by gear cutting, resulting in a gear with 2 meshing surfaces. This worm gear can rotate at high speeds and still operate quietly.

A worm wheel with a cycloid pitch is a more efficient worm gear. It reduces friction between the worm and the gear, resulting in greater durability, improved operating efficiency, and reduced noise. This pitch line also helps the worm wheel engage more evenly and smoothly. Moreover, it prevents interference with their appearance. It also makes worm wheel and gear engagement smoother.

Calculation of worm shaft deflection

There are several methods for calculating worm shaft deflection, and each method has its own set of disadvantages. These commonly used methods provide good approximations but are inadequate for determining the actual worm shaft deflection. For example, these methods do not account for the geometric modifications to the worm, such as its helical winding of teeth. Furthermore, they overestimate the stiffening effect of the gearing. Hence, efficient thin worm shaft designs require other approaches.

Fortunately, several methods exist to determine the maximum worm shaft deflection. These methods use the finite element method, and include boundary conditions and parameter calculations. Here, we look at a couple of methods. The first method, DIN 3996, calculates the maximum worm shaft deflection based on the test results, while the second one, AGMA 6022, uses the root diameter of the worm as the equivalent bending diameter.

The second method focuses on the basic parameters of worm gearing. We’ll take a closer look at each. We’ll examine worm gearing teeth and the geometric factors that influence them. Commonly, the range of worm gearing teeth is 1 to four, but it can be as large as twelve. Choosing the teeth should depend on optimization requirements, including efficiency and weight. For example, if a worm gearing needs to be smaller than the previous model, then a small number of teeth will suffice.

China OEM Precision Steering Shaft Double Hardy Spicer Cardan Moog Drive Car Jeep Truck Automobile Heavy Duty Small Axle Universal U Coupling Joints with Free Design Custom

Product Description

precision steering shaft double hardy spicer cardan moog drive car jeep truck automobile heavy duty small axle universal u joints

What Is a Worm Gear Reducer?

If you have never seen a worm gear reducer before, you’re missing out! Learn more about these incredible gears and their applications by reading this article! In addition to worm gear reducers, learn about worms and how they’re made. You’ll also discover what types of machines can benefit from worm gears, such as rock crushers and elevators. The following information will help you understand what a worm gear reducer is and how to find 1 in your area.

Typical worm shaft

A typical worm has 2 shafts, 1 for advancing and 1 for receding, which form the axial pitch of the gear. Usually, there are 8 standard axial pitches, which establish a basic dimension for worm production and inspection. The axial pitch of the worm equals the circular pitch of the gear in the central plane and the master lead cam’s radial pitch. A single set of change gears and 1 master lead cam are used to produce each size of worm.

Worm gear is commonly used to manufacture a worm shaft. It is a reliable and efficient gear reduction system that does not move when the power is removed. Typical worm gears come in standard sizes as well as assisted systems. Manufacturers can be found online. Listed below are some common materials for worm gears. There are also many options for lubrication. The worm gear is typically made from case hardened steel or bronze. Non-metallic materials are also used in light-duty applications.

A self-locking worm gear prevents the worm from moving backwards. Typical worm gears are generally self-locking when the lead angle is less than 11 degrees. However, this feature can be detrimental to systems that require reverse sensitivity. If the lead angle is less than 4 degrees, back-driving is unlikely. However, if fail-safe protection is a prerequisite, back-driving worm gears must have a positive brake to avoid reverse movement.

Worm gears are often used in transmission applications. They are a more efficient way to reduce the speed of a machine compared to conventional gear sets. Their reduced speed is possible thanks to their low ratio and few components. Unlike conventional gear sets, worm gears require less maintenance and lower mechanical failure than a conventional gear set. While they require fewer parts, worm gears are also more durable than conventional gear sets.

There are 2 types of worm tooth forms. Convex and involute helicoids have different types of teeth. The former uses a straight line to intersect the involute worm generating line. The latter, on the other hand, uses a trapezoid based on the central cross section of the root. Both of these tooth forms are used in the production of worms. And they have various variations in pitch diameter.

Types of worms

Worms have several forms of tooth. For convenience in production, a trapezoid-based tooth form is used. Other forms include an involute helicoidal or a convolute worm generating a line. The following is a description of each type. All types are similar, and some may be preferred over others. Listed below are the 3 most common worm shaft types. Each type has its own advantages and disadvantages.

Discrete versus parallel axis: The design of a worm gear determines its ratio of torque. It’s a combination of 2 different metals – 1 for the worm and 1 for the wheel – which helps it absorb shock loads. Construction equipment and off-road vehicles typically require varying torques to maneuver over different terrain. A worm gear system can help them maneuver over uneven terrain without causing excessive wear.

Worm gear units have the highest ratio. The sliding action of the worm shaft results in a high self-locking torque. Depending on the angle of inclination and friction, a worm gear can reach up to 100:1! Worm gears can be made of different materials depending on their inclination and friction angle. Worm gears are also useful for gear reduction applications, such as lubrication or grinding. However, you should consider that heavier gears tend to be harder to reverse than lighter ones.

Metal alloy: Stainless steel, brass, and aluminum bronze are common materials for worm gears. All 3 types have unique advantages. A bronze worm gear is typically composed of a combination of copper, zinc, and tin. A bronze shaft is more corrosive than a brass one, but it is a durable and corrosion-resistant option. Metal alloys: These materials are used for both the worm wheel.

The efficiency of worm gears depends on the assembly conditions and the lubricant. A 30:1 ratio reduces the efficiency to 81:1%. A worm gear is more efficient at higher ratios than an helical gear, but a 30:1 ratio reduces the efficiency to 81%. A helical gear reduces speed while preserving torque to around 15% of the original speed. The difference in efficiency between worm gear and helical gear is about half an hour!

Methods of manufacturing worm shafts

Several methods of manufacturing worm shafts are available in the market. Single-pointed lathe tools or end mills are the most popular methods for manufacturing worms. These tools are capable of producing worms with different pressure angles depending on their diameter, the depth of thread, and the grinding wheel’s diameter. The diagram below shows how different pressure angles influence the profile of worms manufactured using different cutting tools.

The method for making worm shafts involves the process of establishing the proper outer diameter of a common worm shaft blank. This may include considering the number of reduction ratios in a family, the distance between the worm shaft and the gear set center, as well as the torques involved. These processes are also referred to as ‘thread assembly’. Each process can be further refined if the desired axial pitch can be achieved.

The axial pitch of a worm must match the circular pitch of the larger gear. This is called the pitch. The pitch diameter and axial pitch must be equal. Worms can be left-handed or right-handed. The lead, which refers to the distance a point on the thread travels during 1 revolution of the worm, is defined by its angle of tangent to the helix on the pitch of the cylinder.

Worm shafts are commonly manufactured using a worm gear. Worm gears can be used in different applications because they offer fine adjustment and high gear reduction. They can be made in both standard sizes and assisted systems. Worm shaft manufacturers can be found online. Alternatively, you can contact a manufacturer directly to get your worm gears manufactured. The process will take only a few minutes. If you are looking for a manufacturer of worm gears, you can browse a directory.

Worm gears are made with hardened metal. The worm wheel and gear are yellow in color. A compounded oil with rust and oxidation inhibitors is also used to make worm gears. These oils adhere to the shaft walls and make a protective barrier between the surfaces. If the compounded oil is applied correctly, the worm gear will reduce the noise in a motor, resulting in a smoother performance.

applications for worm gear reducers

Worm gears are widely used in power transmission applications, providing a compact, high reduction, low-speed drive. To determine the torque ratio of worm gears, a numerical model was developed that makes use of the equation of displacement compatibility and the influence coefficient method, which provides fast computing. The numerical model also incorporates bending deflections of the gear surfaces and the mating surfaces. It is based on the Boussinesq theory, which calculates local contact deformations.

Worm gears can be designed to be right or left-handed, and the worm can turn either clockwise or counter-clockwise. An internal helical gear requires the same hand to operate both parts. In contrast, an external helical gear must be operated by the opposite hand. The same principle applies to worm gears in other applications. The torque and power transferred can be large, but worm gears are able to cope with large reductions in both directions.

Worm gears are extremely useful in industrial machinery designs. They reduce noise levels, save space, and give machines extra precision and fast-stopping capabilities. Worm gears are also available in compact versions, making them ideal for hoisting applications. This type of gear reducer is used in industrial settings where space is an issue. Its smaller size and less noise makes it ideal for applications that need the machine to stop quickly.

A double-throated worm gear offers the highest load capacity while still remaining compact. The double-throated version features concave teeth on both worm and gear, doubling the contact area between them. Worm gears are also useful for low to moderate-horsepower applications, and their high ratios, high output torque, and significant speed reduction make them a desirable choice for many applications. Worm gears are also quieter than other types of gears, reducing the noise and vibrations that they cause.

Worm gears have numerous advantages over other types of gears. They have high levels of conformity and can be classified as a screw pair within a lower-pair gear family. Worm gears are also known to have a high degree of relative sliding. Worm gears are often made of hardened steel or phosphor-bronze, which provides good surface finish and rigid positioning. Worm gears are lubricated with special lubricants that contain surface-active additives. Worm gear lubrication is a mixed lubrication process and causes mild wear and tear.

China OEM Universal Joint U Joint, Steering Universal Joints, Drive Shaft Knuckle Eye Flexible Universal Joint with Great quality

Product Description

Universal Joint

Universal Joint with Cardan Shaft

High-grade alloy steel

Rigidity: HRC48~50

Operating angle: 20

Single, double and assemble pin & block universal joints

These universal joints are made from high-grade alloy steel, and been heat treated for anti-oxidation. The surface rigidity is HRC48~50 and the pin & block is HRC60. We could manufacture single, double and assemble pin & block universal joints on requested.

Welcome to send us your product drawings for quotation.

Small quantity order is acceptable.

We pay attention to your inquriy, and take quotation as our important work.

ZheJiang CZPT Electrical Machinery Equipment Co., Ltd

Contact man: Austin.Wang

The Four Basic Components of a Screw Shaft

There are 4 basic components of a screw shaft: the Head, the Thread angle, and the Threaded shank. These components determine the length, shape, and quality of a screw. Understanding how these components work together can make purchasing screws easier. This article will cover these important factors and more. Once you know these, you can select the right type of screw for your project. If you need help choosing the correct type of screw, contact a qualified screw dealer.

Thread angle

The angle of a thread on a screw shaft is the difference between the 2 sides of the thread. Threads that are unified have a 60 degree angle. Screws have 2 parts: a major diameter, also known as the screw’s outside diameter, and a minor diameter, or the screw’s root diameter. A screw or nut has a major diameter and a minor diameter. Each has its own angle, but they all have 1 thing in common – the angle of thread is measured perpendicularly to the screw’s axis.

The pitch of a screw depends on the helix angle of the thread. In a single-start screw, the lead is equal to the pitch, and the thread angle of a multiple-start screw is based on the number of starts. Alternatively, you can use a square-threaded screw. Its square thread minimizes the contact surface between the nut and the screw, which improves efficiency and performance. A square thread requires fewer motors to transfer the same load, making it a good choice for heavy-duty applications.

A screw thread has 4 components. First, there is the pitch. This is the distance between the top and bottom surface of a nut. This is the distance the thread travels in a full revolution of the screw. Next, there is the pitch surface, which is the imaginary cylinder formed by the average of the crest and root height of each tooth. Next, there is the pitch angle, which is the angle between the pitch surface and the gear axis.

Head

There are 3 types of head for screws: flat, round, and hexagonal. They are used in industrial applications and have a flat outer face and a conical interior. Some varieties have a tamper-resistant pin in the head. These are usually used in the fabrication of bicycle parts. Some are lightweight, and can be easily carried from 1 place to another. This article will explain what each type of head is used for, and how to choose the right 1 for your screw.

The major diameter is the largest diameter of the thread. This is the distance between the crest and the root of the thread. The minor diameter is the smaller diameter and is the distance between the major and minor diameters. The minor diameter is half the major diameter. The major diameter is the upper surface of the thread. The minor diameter corresponds to the lower extreme of the thread. The thread angle is proportional to the distance between the major and minor diameters.

Lead screws are a more affordable option. They are easier to manufacture and less expensive than ball screws. They are also more efficient in vertical applications and low-speed operations. Some types of lead screws are also self-locking, and have a high coefficient of friction. Lead screws also have fewer parts. These types of screw shafts are available in various sizes and shapes. If you’re wondering which type of head of screw shaft to buy, this article is for you.

Threaded shank

Wood screws are made up of 2 parts: the head and the shank. The shank is not threaded all the way up. It is only partially threaded and contains the drive. This makes them less likely to overheat. Heads on wood screws include Oval, Round, Hex, Modified Truss, and Flat. Some of these are considered the “top” of the screw.

Screws come in many sizes and thread pitches. An M8 screw has a 1.25-mm thread pitch. The pitch indicates the distance between 2 identical threads. A pitch of 1 is greater than the other. The other is smaller and coarse. In most cases, the pitch of a screw is indicated by the letter M followed by the diameter in millimetres. Unless otherwise stated, the pitch of a screw is greater than its diameter.

Generally, the shank diameter is smaller than the head diameter. A nut with a drilled shank is commonly used. Moreover, a cotter pin nut is similar to a castle nut. Internal threads are usually created using a special tap for very hard metals. This tap must be followed by a regular tap. Slotted machine screws are usually sold packaged with nuts. Lastly, studs are often used in automotive and machine applications.

In general, screws with a metric thread are more difficult to install and remove. Fortunately, there are many different types of screw threads, which make replacing screws a breeze. In addition to these different sizes, many of these screws have safety wire holes to keep them from falling. These are just some of the differences between threaded screw and non-threaded. There are many different types of screw threads, and choosing the right 1 will depend on your needs and your budget.

Point

There are 3 types of screw heads with points: cone, oval, and half-dog. Each point is designed for a particular application, which determines its shape and tip. For screw applications, cone, oval, and half-dog points are common. Full dog points are not common, and they are available in a limited number of sizes and lengths. According to ASTM standards, point penetration contributes as much as 15% of the total holding power of the screw, but a cone-shaped point may be more preferred in some circumstances.

There are several types of set screws, each with its own advantage. Flat-head screws reduce indentation and frequent adjustment. Dog-point screws help maintain a secure grip by securing the collar to the screw shaft. Cup-point set screws, on the other hand, provide a slip-resistant connection. The diameter of a cup-point screw is usually half of its shaft diameter. If the screw is too small, it may slack and cause the screw collar to slip.

The UNF series has a larger area for tensile stress than coarse threads and is less prone to stripping. It’s used for external threads, limited engagement, and thinner walls. When using a UNF, always use a standard tap before a specialized tap. For example, a screw with a UNF point is the same size as a type C screw but with a shorter length.

Spacer

A spacer is an insulating material that sits between 2 parts and centers the shaft of a screw or other fastener. Spacers come in different sizes and shapes. Some of them are made of Teflon, which is thin and has a low coefficient of friction. Other materials used for spacers include steel, which is durable and works well in many applications. Plastic spacers are available in various thicknesses, ranging from 4.6 to 8 mm. They’re suitable for mounting gears and other items that require less contact surface.

These devices are used for precision fastening applications and are essential fastener accessories. They create clearance gaps between the 2 joined surfaces or components and enable the screw or bolt to be torqued correctly. Here’s a quick guide to help you choose the right spacer for the job. There are many different spacers available, and you should never be without one. All you need is a little research and common sense. And once you’re satisfied with your purchase, you can make a more informed decision.

A spacer is a component that allows the components to be spaced appropriately along a screw shaft. This tool is used to keep space between 2 objects, such as the spinning wheel and an adjacent metal structure. It also helps ensure that a competition game piece doesn’t rub against an adjacent metal structure. In addition to its common use, spacers can be used in many different situations. The next time you need a spacer, remember to check that the hole in your screw is threaded.

Nut

A nut is a simple device used to secure a screw shaft. The nut is fixed on each end of the screw shaft and rotates along its length. The nut is rotated by a motor, usually a stepper motor, which uses beam coupling to accommodate misalignments in the high-speed movement of the screw. Nuts are used to secure screw shafts to machined parts, and also to mount bearings on adapter sleeves and withdrawal sleeves.

There are several types of nut for screw shafts. Some have radial anti-backlash properties, which prevent unwanted radial clearances. In addition, they are designed to compensate for thread wear. Several nut styles are available, including anti-backlash radial nuts, which have a spring that pushes down on the nut’s flexible fingers. Axial anti-backlash nuts also provide thread-locking properties.

To install a ball nut, you must first align the tangs of the ball and nut. Then, you must place the adjusting nut on the shaft and tighten it against the spacer and spring washer. Then, you need to lubricate the threads, the ball grooves, and the spring washers. Once you’ve installed the nut, you can now install the ball screw assembly.

A nut for screw shaft can be made with either a ball or a socket. These types differ from hex nuts in that they don’t need end support bearings, and are rigidly mounted at the ends. These screws can also have internal cooling mechanisms to improve rigidity. In this way, they are easier to tension than rotating screws. You can also buy hollow stationary screws for rotator nut assemblies. This type is great for applications requiring high heat and wide temperature changes, but you should be sure to follow the manufacturer’s instructions.

China manufacturer Manufacturer China OEM 43420-33250 Auto Parts Car Front Drive Axle Shaft Assembly Supplier with Good quality

Design: RAV 4 II (_A2_), RAV 4 III (_A3_)

Year: 2005-, 2000-2005

OE NO.: 43420-33250

Automobile Fitment: Toyota

Reference NO.: 3571338, .571338, GI-239

Size: Normal

Substance: Steel

Product Quantity: 43420-33250

Warranty: 12 Months

Car Make: Automobile

Merchandise Name: travel shaft

OEM: 43420-33250

Packing: 1.neutral packing 2.fengming packing 3.in accordance to customer’s ask for

Payment: T/T. 30% Deposit.Western Union.paypal

Shade: Image

MOQ: 2 Pcs

Car Model: Vehicle

High quality: Higher Degree

Shipping time: Within 7 Times

Sample: Presented

Packaging Information: Axle Push Shaft Packing:1.neutral packing 2.fengming packing 3.according to customer’s request

Producer China OEM 43420-33250 Vehicle Elements Automobile Front Push Axle Shaft Assembly SupplierManufacturer China OEM 43420-33250 Auto Elements Vehicle Entrance Generate Axle Shaft Assembly Supplier

Specification

1.merchandise Title:Vehicle Axle Generate Shaft 2.OEM NO: 43420-33250 3.PACKING Neutral Packing,fengming packging,as cuetomers’ request 4.Shipping Time: Generally Within 3-10 days after deposit or as customers’ need, 4 seater off highway petrol golfing cart for salegolf buggy for sale count on stock5. transport By sea,by categorical,DHL,by air6. payment PayPal,Western Union,T/T7.Benefits: Our Positive aspects:

1. Authentic good quality,Good good quality, cost-effective and convenient transportation.2. We have sufficient products in stock to guarantee the shortest shipping time.

three. Following-product sales support evaluation is very good, any troubles will be actively dealt with, PHF42 Sequence Planetary Gearbox,Gearbox,planetary equipment reducer, servo gearbox to give buyers the greatest purchasing knowledge.

Product Specifics

Very hot Sale

Company Profile

Generation Line

Q1How numerous years have your organization dealt in autoparts?

A: We have been established for 6 several years now

Q2. What is your organization major goods?

A: Our main products are Spark Plug, Brake Pad, Oil Fiter. Gasoline Filter, Air Fiter, Engine

Belt, Shock Absorber, Control Arm, Ball Joint, Tie Rod Stop, eighteen fourteen 38 12 34 1” 2” twelve-4 Inch Cnc Turned Brass Bushing Stabilizer Hyperlink Rod, Wheel

Hub Bearing, C.v.joint, Automobile Gentle, ect.

03. What automobiles are your components for?

A: Our parts are maily for BMW, Benz, Toyota, Porsche, Ford, PVFN90 Nema 34 42 Precision Ratio one hundred fifty Spur Equipment ninety Degree Right Angle Planetary Gearbox Volkswagen, Land Rover and so forth.

Q4. Are you a manufacturing facility or investing company?

A: We are Producing and Investing Fengming

05. What is the MOQ?

A: Normally we can provide any amount if we have stock.

06. What is the shipping and delivery date?

A: It requires 5-7 times if there is stock, but will take about thirty times if there is no inventory.

Our Team

Our Residence Simply click listed here again to property

OEM 43430-60060 Auto Areas Vehicle Entrance Generate Axle Shaft Assembly Supplier

OEM 43430-60060 Automobile Parts Car Front Travel Axle Shaft Assembly Provider

OEM 43430-60060 Car Elements Automobile Front Generate Axle Shaft Assembly Provider

Driveshaft construction and vibrations related with it

The structure of the drive shaft is essential to its efficiency and dependability. Travel shafts generally contain claw couplings, rag joints and universal joints. Other drive shafts have prismatic or splined joints. Find out about the diverse types of generate shafts and how they perform. If you want to know the vibrations associated with them, read on. But 1st, let’s outline what a driveshaft is.

transmission shaft

As the demand from customers on our automobiles continues to boost, so does the demand from customers on our push techniques. Increased CO2 emission expectations and stricter emission specifications enhance the pressure on the travel method while strengthening ease and comfort and shortening the turning radius. These and other unfavorable results can area substantial tension and put on on elements, which can direct to driveshaft failure and improve vehicle basic safety hazards. As a result, the generate shaft must be inspected and changed routinely.

Based on your design, you may only need to have to replace a single driveshaft. Nevertheless, the expense to replace both driveshafts ranges from $650 to $1850. Moreover, you could incur labor expenses ranging from $one hundred forty to $250. The labor price tag will rely on your automobile product and its drivetrain type. In common, however, the cost of replacing a driveshaft ranges from $470 to $1850.

Regionally, the automotive driveshaft market place can be divided into four significant marketplaces: North The us, Europe, Asia Pacific, and Rest of the Planet. North America is anticipated to dominate the marketplace, while Europe and Asia Pacific are expected to increase the swiftest. Moreover, the market place is envisioned to grow at the maximum rate in the long term, pushed by economic progress in the Asia Pacific area. In addition, most of the automobiles marketed globally are produced in these locations.

The most essential attribute of the driveshaft is to transfer the electrical power of the motor to helpful operate. Push shafts are also known as propeller shafts and cardan shafts. In a vehicle, a propshaft transfers torque from the engine, transmission, and differential to the entrance or rear wheels, or each. Owing to the complexity of driveshaft assemblies, they are essential to motor vehicle safety. In addition to transmitting torque from the motor, they must also compensate for deflection, angular alterations and duration adjustments.

kind

Distinct types of travel shafts include helical shafts, gear shafts, worm shafts, planetary shafts and synchronous shafts. Radial protruding pins on the head offer a rotationally secure connection. At minimum one particular bearing has a groove extending alongside its circumferential size that enables the pin to pass by way of the bearing. There can also be two flanges on every stop of the shaft. Relying on the application, the shaft can be installed in the most handy area to perform.

Propeller shafts are typically created of high-good quality metal with high certain energy and modulus. However, they can also be manufactured from innovative composite components this kind of as carbon fiber, Kevlar and fiberglass. An additional sort of propeller shaft is created of thermoplastic polyamide, which is rigid and has a higher energy-to-excess weight ratio. The two drive shafts and screw shafts are utilized to drive vehicles, ships and bikes.

Sliding and tubular yokes are widespread factors of drive shafts. By style, their angles should be equal or intersect to provide the proper angle of procedure. Until the functioning angles are equal, the shaft vibrates 2 times for every revolution, triggering torsional vibrations. The very best way to stay away from this is to make positive the two yokes are correctly aligned. Crucially, these parts have the same functioning angle to ensure clean electricity movement.

The type of generate shaft differs according to the variety of motor. Some are geared, even though other people are non-geared. In some circumstances, the generate shaft is set and the motor can rotate and steer. Alternatively, a versatile shaft can be used to management the velocity and course of the travel. In some programs the place linear power transmission is not attainable, flexible shafts are a beneficial alternative. For case in point, versatile shafts can be utilised in transportable products.

place up

The design of the push shaft has several rewards more than bare metallic. A shaft that is versatile in numerous instructions is simpler to sustain than a shaft that is rigid in other instructions. The shaft physique and coupling flange can be made of various materials, and the flange can be created of a distinct substance than the major shaft body. For example, the coupling flange can be produced of metal. The primary shaft body is preferably flared on at the very least one finish, and the at minimum one particular coupling flange includes a first typically frustoconical projection extending into the flared stop of the primary shaft physique.

The standard stiffness of fiber-based mostly shafts is reached by the orientation of parallel fibers together the length of the shaft. Nevertheless, the bending stiffness of this shaft is diminished due to the alter in fiber orientation. Because the fibers continue to vacation in the exact same path from the very first stop to the next conclude, the reinforcement that raises the torsional stiffness of the shaft is not affected. In contrast, a fiber-based mostly shaft is also flexible since it makes use of ribs that are about ninety degrees from the centerline of the shaft.

In addition to the helical ribs, the generate shaft a hundred could also incorporate reinforcing components. These reinforcing components preserve the structural integrity of the shaft. These reinforcing aspects are referred to as helical ribs. They have ribs on the two the outer and inner surfaces. This is to avoid shaft breakage. These elements can also be shaped to be adaptable enough to accommodate some of the forces created by the drive. Shafts can be designed employing these techniques and manufactured into worm-like generate shafts.

vibration

The most widespread lead to of drive shaft vibration is inappropriate installation. There are 5 typical sorts of driveshaft vibration, each and every associated to installation parameters. To prevent this from taking place, you must realize what causes these vibrations and how to correct them. The most frequent kinds of vibration are listed below. This report describes some frequent push shaft vibration answers. It could also be advantageous to take into account the advice of a expert vibration technician for drive shaft vibration management.

If you happen to be not sure if the dilemma is the driveshaft or the engine, try turning on the stereo. Thicker carpet kits can also mask vibrations. Nonetheless, you need to make contact with an specialist as shortly as achievable. If vibration persists soon after vibration-related repairs, the driveshaft requirements to be changed. If the driveshaft is still below guarantee, you can mend it your self.

CV joints are the most typical trigger of third-get driveshaft vibration. If they are binding or are unsuccessful, they need to have to be replaced. Alternatively, your CV joints could just be misaligned. If it is free, you can verify the CV connector. Yet another common result in of generate shaft vibration is inappropriate assembly. Incorrect alignment of the yokes on the two ends of the shaft can result in them to vibrate.

Incorrect trim peak can also lead to driveshaft vibration. Right trim height is needed to avoid push shaft wobble. Regardless of whether your car is new or old, you can execute some basic fixes to reduce troubles. One of these answers entails balancing the push shaft. 1st, use the hose clamps to connect the weights to it. Up coming, connect an ounce of fat to it and spin it. By undertaking this, you decrease the frequency of vibration.

value

The worldwide driveshaft market is anticipated to exceed (xxx) million USD by 2028, increasing at a compound annual development rate (CAGR) of XX%. Its soaring growth can be attributed to several elements, which includes escalating urbanization and R&D investments by major market place players. The report also involves an in-depth examination of crucial marketplace tendencies and their affect on the sector. Moreover, the report offers a thorough regional evaluation of the Driveshaft Industry.

The value of changing the generate shaft relies upon on the kind of mend essential and the trigger of the failure. Typical fix fees selection from $300 to $750. Rear-wheel travel automobiles typically price far more. But front-wheel drive automobiles cost less than 4-wheel travel vehicles. You may possibly also choose to attempt fixing the driveshaft your self. Even so, it is important to do your research and make positive you have the needed equipment and equipment to perform the work effectively.

The report also covers the competitive landscape of the Travel Shafts market place. It includes graphical representations, in depth statistics, management guidelines, and governance elements. In addition, it contains a comprehensive expense evaluation. Furthermore, the report offers sights on the COVID-19 market and foreseeable future tendencies. The report also offers useful information to assist you choose how to compete in your sector. When you acquire a report like this, you are incorporating credibility to your work.

A top quality driveshaft can improve your game by ensuring distance from the tee and bettering responsiveness. The new material in the shaft construction is lighter, more robust and much more responsive than ever ahead of, so it is turning out to be a key part of the driver. And there are a variety of possibilities to fit any spending budget. The primary issue to take into account when buying a shaft is its quality. Nevertheless, it’s crucial to observe that good quality does not occur low-cost and you need to often choose an axle based on what your budget can deal with.

China Custom Kawacvjoints OEM 2200400U2212 Front Drive Shaft CV Joint Axle for JAC S3 1.5L MT R near me manufacturer

Model: REFINE S3, REFINE S3 SUV, S3, T5 / T50, REFINE S3 Closed Off-Street Car

Year: 2014-, 2019-

OE NO.: 2200400U2212

Auto Fitment: JAC

Reference NO.: 12-216001

Size: 12*twelve*seventy five

Substance: Metal

Design Amount: 2200400U2212

Warranty: 31069 HangZhous

Car Make: JAC S3 1.5L MT R

OE: 2200400U2212

Product Title: CV Joint Axle

MOQ: ten Pcs

Certification: ISO9001

Packing: Neutral Packing

Value: Make contact with us

Position: Front Left Appropriate

Brand name: Kawacvjoints

Advantage: 20 Many years Knowledge

Shipping and delivery time: 7-30 Days

Packaging Information: PACKING: PACKING BOX IS Exact same AS CLIENT’S BOX , Every CV JOINT BE PACKED IN A single BOX WITH Restore KITS, THEN 4 Packing containers IN One particular CARTON

Please speak to us to verify your versions Goods Description Automotive Chassis Areas Transmission Drive Shaft C.V. Axle NameDRIVESHAFTOE No.2200400U2212Car Product:JAC S3 1.5L MT RWarranty50000 kmMOQ10PCS Specifications1. We have complete assortment for several common design push shaft.2. Over 20 many years of production vehicle components.3. 50000 km high quality assure.4. 100% Inspection just before shipment. Packing & SP105715 FILTER 571131053 of Gearbox for Wheel Loader Supply Packing Details : Box+carton+palletDelivery Details : 5-30 days following purchase concluded.Generally it is 5-7 days if the items are in inventory. Or it is fifteen-20 days if the items are not, it is in accordance to thequantity. Business Profile About us.We have been specializing in the generation of automotive factors and accessories considering that 2003. We created our model “Kawacvjoints”, aiming to create it to 1 of the most renowned auto components maker. We have our personal manufacturing facility and all our merchandise are developed below rigorous regulation.We guarantee to provide our clients with higher quality and outstanding items of all time. Our Manufacturing unit Suggest Merchandise FAQ Q1. What is your terms of packing?A: Typically, we pack our goods in neutral brown containers and brown cartons. If you have lawfully registered patent, we can pack the items in your branded boxes soon after obtaining your authorization letters.Q2. What is your terms of payment?A: T/T thirty% as deposit, and 70% before shipping and delivery. We’ High quality new layout cast iron elevator pulley industrial wheel ll present you the images of the goods and offers prior to you pay the balance.Q3. What is your phrases of shipping?A: EXW, FOB, CFR, CIF, DDU.Q4. How about your delivery time?A: Generally, it will get 30 to sixty days following getting your progress payment. The specific shipping time depends on the things and the amount of your get.Q5. Can you make according to the samples?A: Indeed, we can generate by your samples or specialized drawings. We can create the molds and fixtures.Q6. What is your sample plan?A: We can supply the sample if we have ready parts in stock, but the clients have to pay the sample expense and the courier value.Q7. Do you examination all your merchandise ahead of shipping and delivery?A: Sure, Manufacturing facility Outlet Truck Transmission h2o inlet pipe Gearbox outlet pipe Cooling program outlet pipe we have 100% check ahead of deliveryQ8: How do you make our enterprise prolonged-phrase and great partnership?A:1. We maintain very good quality and competitive price tag to make sure our customers advantage 2. We regard each and every client as our pal and we sincerely do enterprise and make friends with them, no subject where they appear from.

What is a driveshaft and how a lot does it price to exchange one particular?

Your vehicle is manufactured up of a lot of shifting areas. Being aware of each part is crucial due to the fact a ruined driveshaft can significantly damage other components of the vehicle. You may possibly not know how important your driveshaft is, but it truly is important to know if you want to resolve your car. In this post, we are going to discuss what a driveshaft is, what its signs are, and how much it charges to change a driveshaft.

Fix damaged driveshafts

A broken driveshaft does not permit you to switch the wheels freely. It also exposes your vehicle to increased restore expenses due to destroyed driveshafts. If the drive shaft breaks while the auto is in movement, it may possibly trigger a crash. Also, it can drastically affect the overall performance of the car. If you never correct the problem right absent, you could threat a lot more pricey repairs. If you suspect that the generate shaft is damaged, do the pursuing.

1st, make sure the travel shaft is protected from dust, humidity, and dust. A correct driveshaft protect will stop grease from accumulating in the driveshaft, decreasing the likelihood of additional injury. The grease will also cushion the metallic-to-metallic make contact with in the continual velocity joints. For illustration, hitting a delicate materials is better than hitting a metal wall. A broken prop shaft can not only result in difficult cornering, but it can also cause the motor vehicle to vibrate, which can further injury the rest of the drivetrain.

If the driveshaft is ruined, you can pick to repair it by yourself or consider it to a mechanic. Typically, driveshaft repairs price close to $200 to $300. Components and labor might differ primarily based on your car type and sort of repair. These components can expense up to $600. Even so, if you will not have a mechanical history, it truly is far better to depart it to a skilled.

If you discover that one particular of the two push shafts is worn, it truly is time to restore it. Worn bushings and bearings can result in the push shaft to vibrate unnecessarily, leading to it to break and cause more hurt. You can also check the middle bearing if there is any perform in the bearing. If these indicators take place, it is best to consider your automobile to a mechanic as quickly as achievable.

Find out about U-joints

Although most autos have at minimum 1 sort of U-joint, there are other varieties accessible. CV joints (also known as hot rod joints) are used in a variety of programs. The small axis is shorter than the main axis on which the U-joint is positioned. In the two circumstances, the U-joints are lubricated at the manufacturing facility. For the duration of servicing, the push shaft slip joint should be lubricated.

There are two principal styles of U-joints, which includes solid and push fit. They are usually held in area by C-clamps. Some of these U-joints have knurls or grooves. When picking the correct fitting, be certain to measure the whole fitting. To make sure you get the right dimensions, you can use the dimension chart or check out the handbook for your specific model.

In addition to lubrication, the problem of the U-joint need to be checked regularly. Lubricate them routinely to avoid premature failure. If you listen to a clicking audio when shifting gears, the u-joint area could be misaligned. In this circumstance, the bearing could need to be serviced. If there is inadequate grease in the bearings, the common joint may need to have to be changed.

U-joint is an essential portion of the car transmission shaft. With no them, your car would have no wheeled suspension. Without having them, your vehicle will have a rickety entrance finish and a wobbly rear end. Simply because vehicles cannot drive on extremely-flat surfaces, they require adaptable driveshafts. The U-joint compensates for this by permitting it to shift up and down with the suspension.

A suitable inspection will establish if your u-joints are free or worn. It should be effortless to pull them out. Make sure not to pull them all the way out. Also, the bearing caps ought to not transfer. Any signs of roughness or wear would reveal a need to have for a new UJ. Also, it is crucial to note that worn UJs cannot be fixed.

Indicators of Driveshaft Failure

One of the most typical troubles connected with a faulty driveshaft is problems turning the wheels. This seriously limits your general manage in excess of the motor vehicle. The good news is, there are numerous indicators that could reveal that your driveshaft is failing. You ought to just take fast actions to establish the lead to of the difficulty. A single of the most common causes of driveshaft failure is a weak or defective reverse gear. Other frequent brings about of driveshaft harm include driving way too challenging, receiving caught in reverse gear and differential lock.

An additional indication of a failed driveshaft is unusual sounds whilst driving. These noises are usually the consequence of put on on the bushings and bearings that assist the push shaft. They can also lead to your car to screech or scratch when switching from drive to idle. Relying on the pace, the sounds may possibly be accompanied by vibration. When this happens, it’s time to deliver your automobile in for a driveshaft substitution.

One particular of the most common symptoms of driveshaft failure is apparent jitter when accelerating. This could be a signal of a unfastened U-joint or worn heart bearing. You must thoroughly examine your automobile to decide the cause of these appears and corresponding signs. A licensed mechanic can support you figure out the lead to of the sound. A broken propshaft can seriously limit the drivability of the vehicle.

Regular inspection of the push shaft can prevent significant damage. Based on the injury, you can change the driveshaft for anywhere from $500 to $1,000. Depending on the severity of the hurt and the amount of repair, the value will rely on the quantity of elements that need to have to be replaced. Do not travel with a poor driveshaft as it can lead to a serious crash. There are many approaches to steer clear of this difficulty completely.

The initial symptom to seem for is a worn U-joint. If the U-joint arrives unfastened or moves too considerably when making an attempt to switch the steering wheel, the driveshaft is faulty. If you see noticeable rust on the bearing cap seals, you can take your automobile to a mechanic for a extensive inspection. A worn u-joint can also point out a issue with the transmission.

The cost of changing the drive shaft

Depending on your state and services centre, a driveshaft mend can cost as little as $three hundred or as large as $2,000, dependent on the specifics of your automobile. Labor expenses are normally all around $70. Costs for the components by themselves variety from $400 to $600. Labor expenses also vary by design and automobile make. Ultimately, the decision to mend or substitute the driveshaft will rely on regardless of whether you need a rapid vehicle fix or a total vehicle repair.

Some cars have two different driveshafts. One particular goes to the entrance and the other goes to the again. If your vehicle has four wheel travel, you will have two. If you are replacing the axles of an all-wheel-travel vehicle, you are going to require a unique portion for every single axle. Choosing the wrong one particular can end result in a lot more high-priced repairs. Just before you commence searching, you ought to know specifically how significantly it will value.

Dependent on the kind of car you personal, a driveshaft substitute will price among PS250 and PS500. Luxury autos can cost as a lot as PS400. However, for security and the total overall performance of the vehicle, replacing the driveshaft may possibly be a essential restore. The price of replacing a driveshaft relies upon on how lengthy your car has been on the road and how significantly wear and tear it has experienced. There are some symptoms that reveal a defective push shaft and you should take immediate action.

Repairs can be pricey, so it’s greatest to employ a mechanic with encounter in the field. You will be investing hundreds of pounds a thirty day period, but you’ll have peace of thoughts being aware of the job will be carried out right. Don’t forget that you could want to question a friend or family members member to help you. Based on the make and model of your auto, replacing the driveshaft is far more high-priced than changing the areas and carrying out it oneself.

If you suspect that your drive shaft is ruined, be positive to repair it as shortly as feasible. It is not a good idea to travel a auto with abnormal vibration and sound for a prolonged time. The good news is, there are some rapid methods to correct the issue and avoid pricey repairs afterwards. If you have seen the indicators previously mentioned, it is well worth getting the task carried out. There are several symptoms that your driveshaft could need to have support, which includes lack of power or trouble relocating the car.