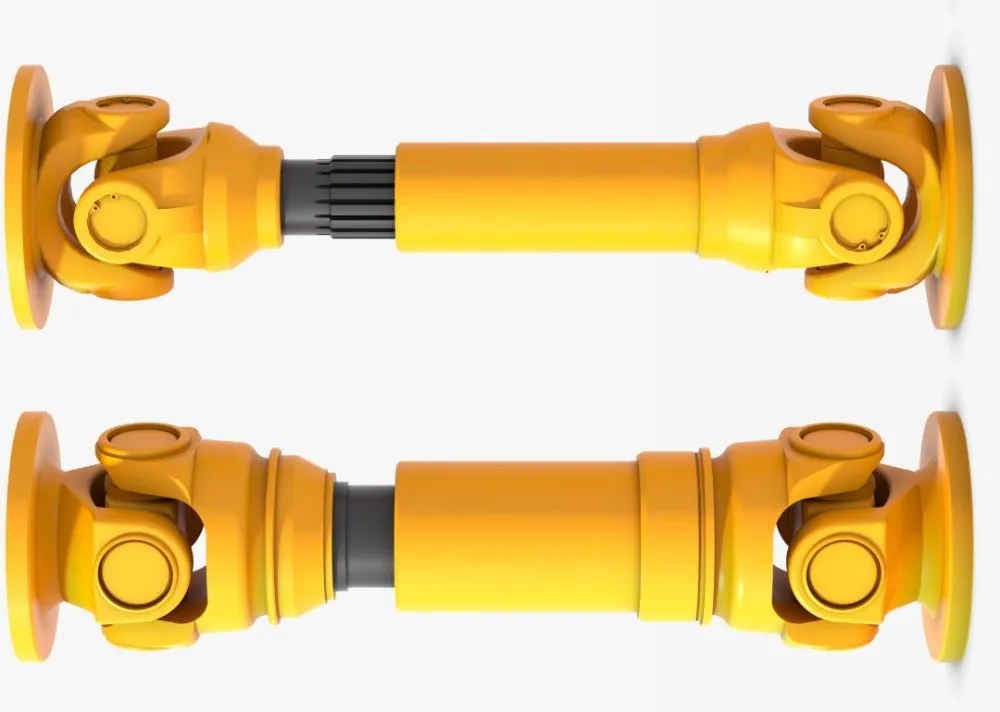

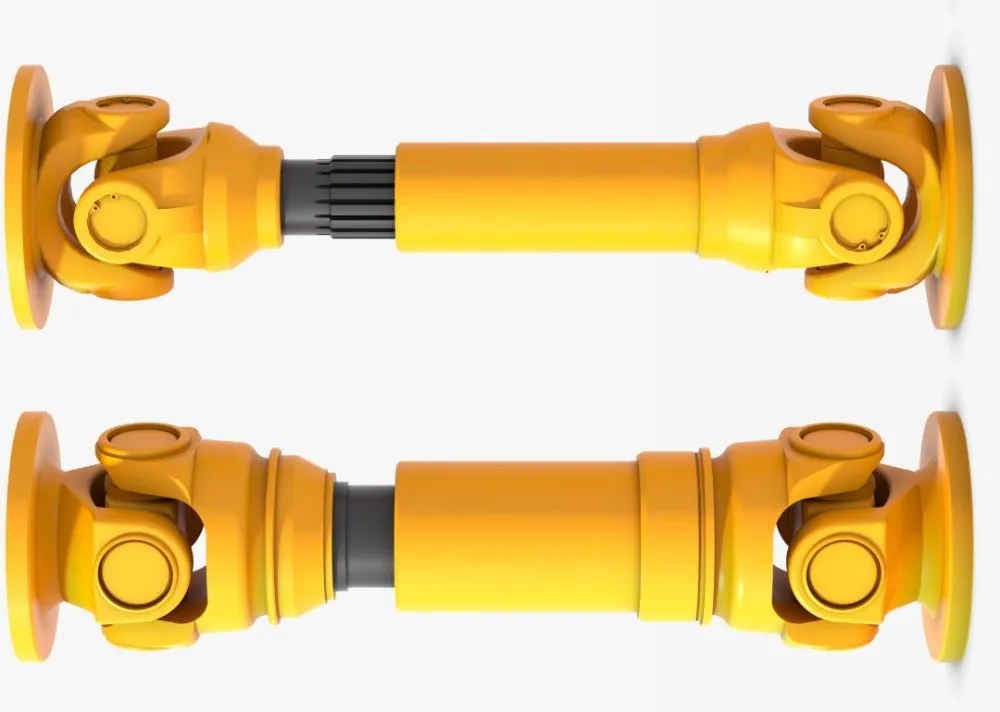

Product Description

Product Parameters

|

item |

value |

|

Warranty |

6-12 Month |

|

Applicable Industries |

Building Material Shops, Manufacturing Plant, Machinery Repair Shops, Retail, Construction works , Energy & Mining |

|

Customized support |

OEM, ODM, OBM |

|

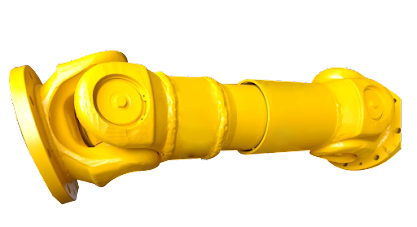

Structure |

Single |

|

Material |

20CR 40CR |

|

Operating Angle |

35 degree |

|

Place of CHINAMFG |

China |

|

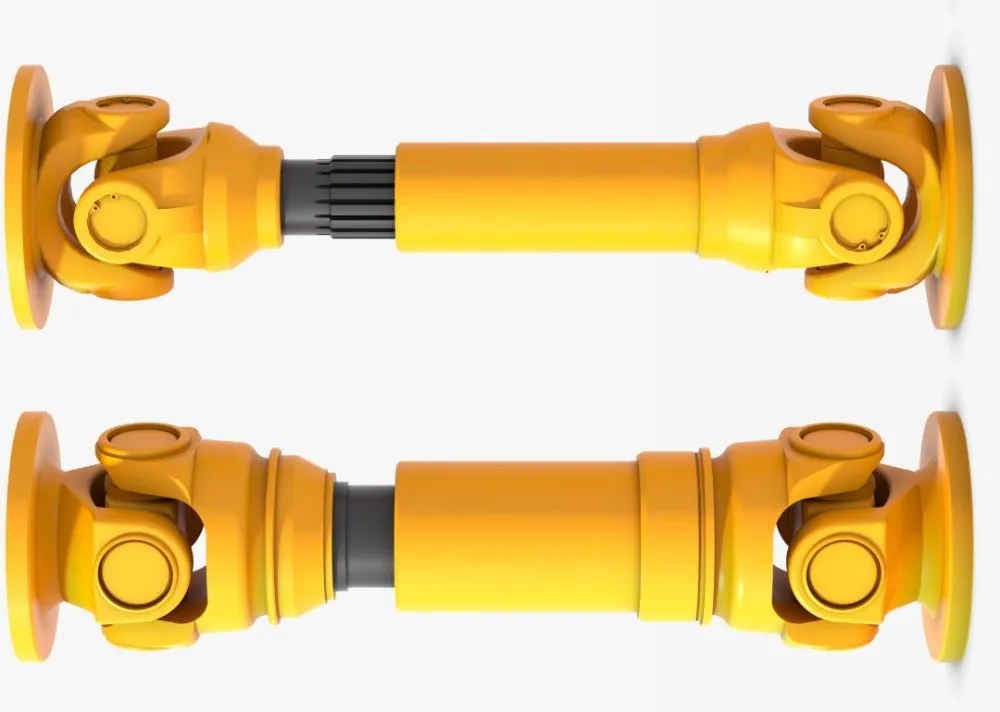

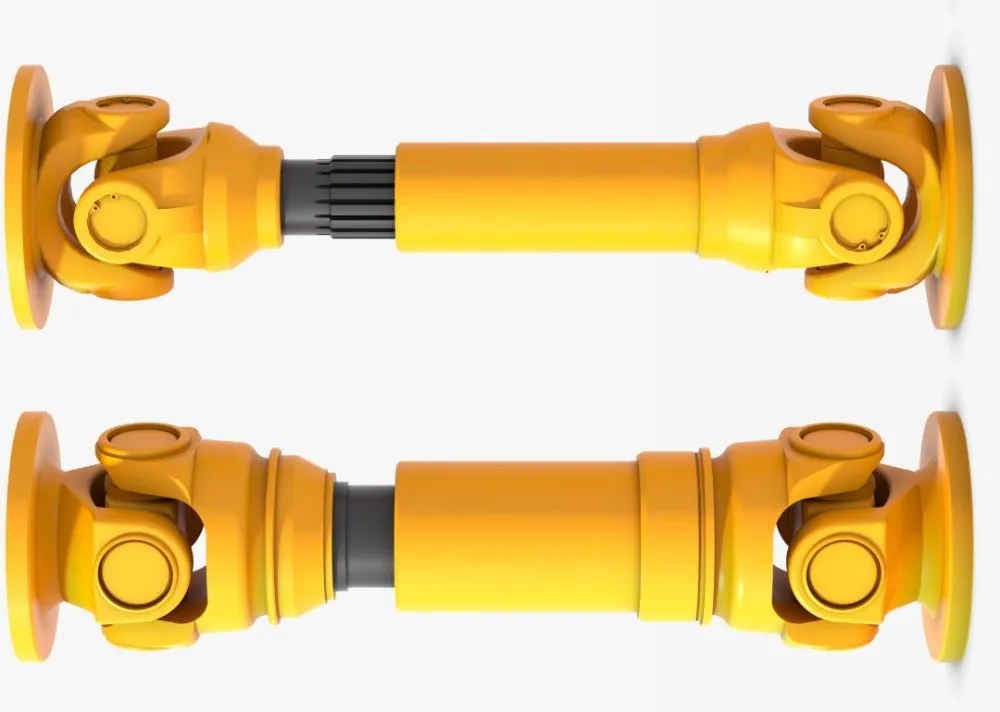

Product Name |

Cross Universal Coupling |

|

Structure |

Single Double Telescopic |

|

Packing |

Under Client’s Requestment |

|

Application |

Automotive.tractor.construction Machinery.rolling Mill |

|

Feature |

Low Noise. Long Life |

|

Precision |

ABEC1 ABEC3 ABEC 5 ABEC7 |

|

Quality |

Original Parts Standard |

|

Service |

OEM Customized Services |

|

MOQ |

10 Pcs |

|

Lead Time |

3-10 days |

Certifications

Company Profile

HangZhou CHINAMFG BEARING Co., Ltd is specialized in bearings areas since 2013, we create an innovative sales service of bearings to satisfy diffierent kinds of application.

We are located in HangZhou city, ZHangZhoug province, China, near HangZhou and ZheJiang port, which has recognized by special ISO, with CE certificiate, The various bearings we produce there have been inspected and confirmed by SGS to be RoHS compliant.

We Registered “GNYAR” in 2014, registered “MAJC” in 2018, both was received in high-performance praise, and earned high reputation. Our products is widely used to mining machinery, motorcycle parts, agricultural machine, auto parts and embroidery machine spare parts, Power tools, bicycle, Semiconductor Facilities. Fitness Equipments, Toys, fishing, industrial using design, etc.

After years of development, we believe that by establishing a mutually beneficial relationship with our customers we can both continue to grow and prosper, we wish and hope to always grant you satisfaction.

Packaging & Shipping

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| After-sales Service: | 1 Year |

|---|---|

| Condition: | New |

| Type: | Universal Joint |

| Material: | Steel |

| Market Type: | After-Market |

| Delivery Time: | 15 – 45days |

| Samples: |

US$ 1/Piece

1 Piece(Min.Order) | |

|---|

| Customization: |

Available

| Customized Request |

|---|

Can cardan joints be used in both horizontal and vertical orientations?

Yes, cardan joints can be used in both horizontal and vertical orientations. Cardan joints, also known as universal joints, are flexible mechanical couplings that transmit torque between misaligned shafts. Their design allows for angular movement and compensation of misalignments in various orientations. Here’s a detailed explanation of how cardan joints can be used in both horizontal and vertical orientations:

Horizontal Orientation: In a horizontal orientation, the input and output shafts of the cardan joint are aligned horizontally, typically parallel to the ground. The joint is capable of transmitting torque smoothly and efficiently between the misaligned shafts while accommodating angular, parallel, and axial misalignments. This makes it suitable for a wide range of horizontal applications, including automotive drivetrains, industrial machinery, and agricultural equipment.

Vertical Orientation: In a vertical orientation, the input and output shafts of the cardan joint are aligned vertically, with one shaft positioned above the other. The joint is still capable of transmitting torque and compensating for misalignments in this configuration. However, it is important to consider the effects of gravity and the additional load imposed on the joint due to the weight of the shafts and any connected components. Adequate support and proper bearing selection should be considered to ensure reliable operation in vertical applications.

Whether in horizontal or vertical orientations, cardan joints offer several advantages that make them versatile for various applications:

- Misalignment Compensation: Cardan joints excel at compensating for angular, parallel, and axial misalignments between shafts. This flexibility allows for smooth torque transmission and reduces stress on the connected components.

- Torque Transmission: Cardan joints are capable of transmitting high levels of torque between misaligned shafts. This makes them suitable for applications that require the transfer of substantial power.

- Durability: Cardan joints are typically constructed from durable materials, such as alloy steels, which provide excellent strength and resistance to fatigue and wear. This durability enables them to withstand the demands of various orientations and operating conditions.

- Compact Design: Cardan joints have a compact design, allowing for efficient installation and integration within the system, regardless of the orientation. This is particularly advantageous in applications with space constraints.

- Versatility: Cardan joints are available in various sizes and configurations to accommodate different orientations and applications. They can be customized to meet specific torque and speed requirements.

It is important to note that specific considerations may apply depending on the application and the magnitude of misalignments. Factors such as load capacity, lubrication, bearing arrangement, and maintenance should be taken into account to ensure optimal performance and longevity of the cardan joint.

In summary, cardan joints can be used in both horizontal and vertical orientations due to their ability to compensate for misalignments and transmit torque between shafts. Their versatility, durability, and compact design make them suitable for a wide range of applications in various orientations.

Can cardan joints be used in robotics and automation?

Yes, cardan joints can be used in robotics and automation applications, depending on the specific requirements and constraints of the system. Cardan joints offer certain advantages and considerations that make them suitable for certain robotic and automation tasks. Here’s a detailed explanation:

1. Flexibility and Misalignment Compensation: Cardan joints are designed to accommodate misalignment between rotating shafts. In robotics and automation, where multiple axes of movement are often involved, cardan joints can provide the necessary flexibility to handle misalignments and angular variations. They can compensate for misalignments resulting from assembly tolerances, thermal expansion, or mechanical deflections, allowing smooth and continuous motion.

2. Torque Transmission: Cardan joints are capable of transmitting torque between shafts at various angles. In robotics and automation, where power needs to be transferred between different components or joints, cardan joints can efficiently transmit torque, even when the shafts are not perfectly aligned. This enables the robot or automated system to perform complex tasks involving multi-axis motion and power transmission.

3. Rotational Freedom: Cardan joints provide rotational freedom and allow for angular movement. This is advantageous in robotics and automation applications where the system requires articulation and maneuverability. The universal joint design of cardan joints allows for smooth rotation and enables the robot or automated system to reach different orientations and perform tasks in various configurations.

4. Compact Design: Cardan joints have a relatively compact design, which can be beneficial in space-constrained robotics and automation setups. The compact size allows for efficient integration into robotic arms, end-effectors, or other automated mechanisms, minimizing the overall footprint and maximizing the utilization of available space.

5. Considerations for Precision and Backlash: When considering the use of cardan joints in robotics and automation, it’s important to account for precision requirements. Cardan joints have inherent clearances or play, which can introduce backlash and affect the system’s accuracy. In applications where high precision is crucial, additional measures such as backlash compensation mechanisms or precision-aligned cardan joints may be necessary.

It’s important to note that the suitability of cardan joints in robotics and automation depends on the specific application requirements, load conditions, precision needs, and other factors. Careful evaluation, system design, and integration are necessary to ensure that the cardan joints function optimally and meet the desired performance criteria.

When considering the use of cardan joints in robotics and automation, it is advisable to consult with engineers or experts specializing in robotics, automation, and power transmission systems. They can provide valuable insights and guidance on the selection, integration, and maintenance of cardan joints for specific robotic and automation applications.

How is a cardan joint different from other types of universal joints?

A cardan joint, also known as a universal joint or U-joint, is a specific type of universal joint design. While there are different variations of universal joints, the cardan joint has distinct characteristics that set it apart from other types. Here’s a detailed explanation of how a cardan joint differs from other universal joints:

1. Design and Structure: The cardan joint consists of two yokes and a cross-shaped member called the cross or spider. The yokes are typically fork-shaped and attached to the shafts, while the cross sits in the center, connecting the yokes. In contrast, other types of universal joints, such as the constant-velocity (CV) joint or Rzeppa joint, have different designs and structures. CV joints often use a combination of bearings and balls to transmit motion and maintain constant velocity, making them suitable for applications requiring smooth rotation without speed fluctuations.

2. Misalignment Compensation: One of the primary functions of a cardan joint is to accommodate misalignment between shafts. It can handle angular misalignment, axial misalignment, or a combination of both. The design of the cardan joint allows for the tilting of the cross as the input and output shafts rotate at different speeds. This tilting action compensates for misalignment and allows the joint to transmit motion. Other types of universal joints, such as the Oldham coupling or Hooke’s joint, have different mechanisms for compensating misalignment. For example, the Oldham coupling uses sliding slots and intermediate disks to accommodate misalignment, while Hooke’s joint uses a combination of rotating links and flexible connections.

3. Operating Range: Cardan joints are commonly used in applications where a wide range of operating angles is required. They can effectively transmit motion and torque at various angles, making them suitable for applications with non-collinear shafts. Other types of universal joints may have specific limitations or operating ranges. For instance, some types of CV joints are designed for constant velocity applications and are optimized for specific operating angles or speed ranges.

4. Applications: Cardan joints find applications in various industries, including automotive, industrial machinery, aerospace, and more. They are commonly used in drivetrain systems, power transmission systems, and applications that require flexibility, misalignment compensation, and reliable motion transmission. Other types of universal joints have their own specific applications. For example, CV joints are commonly used in automotive applications, particularly in front-wheel drive systems, where they provide smooth and constant power transmission while accommodating suspension movements.

5. Limitations: While cardan joints offer flexibility and misalignment compensation, they also have certain limitations. At extreme operating angles, cardan joints can introduce non-uniform motion, increased vibration, backlash, and potential loss of efficiency. Other types of universal joints may have their own limitations and considerations depending on their specific design and application requirements.

In summary, a cardan joint, or universal joint, is a specific type of universal joint design that can accommodate misalignment between shafts and transmit motion at various angles. Its structure, misalignment compensation mechanism, operating range, and applications differentiate it from other types of universal joints. Understanding these distinctions is crucial when selecting the appropriate joint for a specific application.

editor by CX 2024-04-26

China Professional Truck Parts 22X55 U-Joints Bearing Universal Joints Crucetas Joints De Cardan Cross

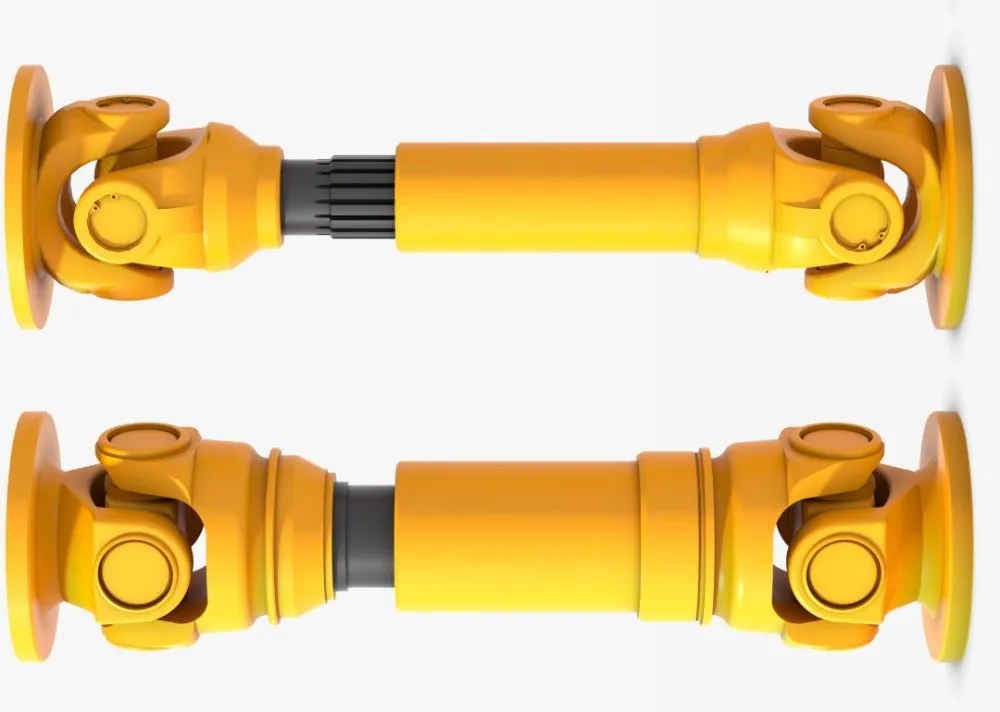

Product Description

Product Description

Universal Coupling Cross Bearing Automobile Bearing Universal Joint Bearing

FAQ

1.Q: How do you pack the bearing ?

A: It is ORIGINAL packaging.

It can be done as your specfic demands.

2.Q: Can I get some samples and do you offer the sample free?

A: Yes, sure, we are honored to offer you samples.If we have stock, we can send you free sample.

And you just need to pay freight. If there have no stock, you need to pay sample fee and freight.

3.Q: Does the sample fee can be return back?

A: If you place an order, we can return part of sample fee even all of fee to you.It also depends

on the Quantity of order and the type of sample.

4.Q: What is the MOQ for bearing?

A: Our MOQ is 1 pc.

5.Q: What is the delivery time?

A: According to the order amount or as your request.

6.Q: Can you promise to deliver bearing CHINAMFG 3530 in time?

A: Credit always ranks the top on the list. We will absolutely deliver the goods in 2-4 days after your order is confirmed.

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Aligning: | Non-Aligning Bearing |

|---|---|

| Separated: | Separated |

| Material: | Bearing Steel |

| Samples: |

US$ 5/Piece

1 Piece(Min.Order) | Order Sample |

|---|

| Customization: |

Available

| Customized Request |

|---|

.shipping-cost-tm .tm-status-off{background: none;padding:0;color: #1470cc}

|

Shipping Cost:

Estimated freight per unit. |

about shipping cost and estimated delivery time. |

|---|

| Payment Method: |

|

|---|---|

|

Initial Payment Full Payment |

| Currency: | US$ |

|---|

| Return&refunds: | You can apply for a refund up to 30 days after receipt of the products. |

|---|

What are the potential challenges in designing and manufacturing cardan joints?

Designing and manufacturing cardan joints can present several challenges that need to be carefully addressed to ensure the functionality, durability, and performance of the joint. Here’s a detailed explanation of the potential challenges in designing and manufacturing cardan joints:

- Misalignment Compensation: One of the primary challenges is designing the joint to effectively compensate for misalignments between the input and output shafts. The joint must accommodate angular, parallel, and axial misalignments while maintaining smooth torque transmission and minimizing stress concentrations.

- Load Capacity and Torque Transmission: Cardan joints are often used in applications that require the transmission of high torque and handling substantial loads. Designing the joint to withstand these loads while ensuring efficient torque transmission can be a challenge. It involves selecting appropriate materials, optimizing the joint’s geometry, and considering factors like bearing capacity and fatigue resistance.

- Bearing Arrangement: Proper bearing arrangement is crucial for the smooth operation and longevity of the cardan joint. Ensuring adequate support and load distribution on the bearings can be challenging, especially in applications with high speeds, heavy loads, or extreme operating conditions. The design must consider factors such as bearing type, size, lubrication, and alignment to optimize performance.

- Compact Design: Cardan joints are often used in systems with limited space, requiring a compact design. Designing a compact joint while maintaining its mechanical properties, load capacity, and misalignment compensation capabilities can be challenging. It involves optimizing the joint’s dimensions, yoke or flange design, and component arrangement to fit within the given space constraints.

- Torsional Rigidity and Vibration: Cardan joints introduce some level of torsional compliance due to their flexible nature. Excessive torsional compliance can lead to vibrations, power loss, and reduced system performance. Designing the joint to provide adequate torsional rigidity while still accommodating misalignments is a challenge that requires careful consideration of the joint’s materials, cross-sectional geometry, and manufacturing processes.

- Manufacturability and Precision: Manufacturing cardan joints with the required precision and quality can be challenging. The joint’s components, such as yokes, cross members, and bearings, need to be manufactured to close tolerances and assembled accurately. Specialized manufacturing techniques, such as forging, machining, and heat treatment, may be required to achieve the desired mechanical properties and dimensional accuracy.

- Material Selection: Selecting the appropriate materials for cardan joints is critical for their performance and durability. The materials must possess high strength, fatigue resistance, and wear resistance to withstand the operating conditions and loads. Balancing material properties, cost considerations, and manufacturability can be challenging during the design process.

- Quality Control and Testing: Ensuring the quality and reliability of cardan joints requires comprehensive testing and quality control measures. Conducting tests to evaluate factors such as torque capacity, misalignment compensation, fatigue life, and dimensional accuracy can be challenging. Implementing effective quality control procedures throughout the manufacturing process is essential to identify and rectify any potential issues.

Addressing these challenges requires a multidisciplinary approach, involving engineering expertise in areas such as mechanical design, materials science, manufacturing processes, and quality assurance. Collaboration between design engineers, manufacturing engineers, and quality control personnel is crucial to overcome these challenges and produce high-quality cardan joints.

It is important to note that the specific challenges may vary depending on the application requirements, industry standards, and operating conditions. Continuous research, development, and advancements in design and manufacturing techniques contribute to overcoming these challenges and improving the performance and reliability of cardan joints.

What are the safety considerations when working with cardan joints?

Working with cardan joints requires careful attention to safety to prevent accidents, injuries, and equipment damage. Cardan joints are mechanical components used for torque transmission and misalignment compensation, and they operate under various loads and conditions. Here are important safety considerations to keep in mind when working with cardan joints:

- Proper Training and Knowledge: Ensure that individuals working with cardan joints have proper training and understanding of their operation, installation, and maintenance. Adequate knowledge of safe working practices, procedures, and potential hazards associated with cardan joints is crucial.

- Personal Protective Equipment (PPE): Use appropriate personal protective equipment, such as safety glasses, gloves, and protective clothing, when handling cardan joints. PPE protects against potential hazards like flying debris, sharp edges, or accidental contact with rotating components.

- Lockout/Tagout: Before performing any maintenance or repair work involving cardan joints, follow lockout/tagout procedures to isolate and de-energize the system. This prevents accidental startup or movement of machinery, ensuring the safety of personnel working on or near the cardan joints.

- Secure Mounting and Fastening: Ensure that cardan joints are securely mounted and properly fastened to prevent unexpected movement or dislodgment during operation. Loose joints or fasteners can lead to component failure, sudden movements, or damage to other parts of the system.

- Torque and Load Limits: Adhere to the recommended torque and load limits specified by the manufacturer for the cardan joints. Exceeding these limits can result in premature wear, deformation, or failure of the joints, posing safety risks and compromising the overall system’s functionality.

- Regular Inspection and Maintenance: Implement a regular inspection and maintenance program for the cardan joints. Inspect for signs of wear, damage, or misalignment, and address any issues promptly. Lubricate the joints according to the manufacturer’s recommendations to ensure smooth operation and prevent excessive friction or overheating.

- Safe Handling and Lifting: When handling or lifting cardan joints, use appropriate lifting equipment and techniques. Cardan joints can be heavy, and improper lifting can lead to strain or injuries. Ensure that lifting devices have the capacity to handle the weight of the joints safely.

- Avoid Contact with Rotating Components: Never reach into or make contact with rotating components of a system that incorporates cardan joints while the system is in operation. Keep loose clothing, jewelry, and other items away from moving parts to prevent entanglement or injury.

- Proper Disposal of Used or Damaged Joints: Follow proper disposal procedures for used or damaged cardan joints. Consult local regulations and guidelines for the disposal of mechanical components to minimize environmental impact and ensure compliance with safety and waste management standards.

- Manufacturer’s Guidelines: Always refer to and follow the manufacturer’s guidelines, instructions, and warnings specific to the cardan joints being used. Manufacturers provide important safety information, installation procedures, and maintenance recommendations specific to their products.

By addressing these safety considerations, individuals can mitigate potential risks associated with working with cardan joints, promote a safe working environment, and ensure the reliable and efficient operation of the systems they are integrated into.

How do you maintain and service a cardan joint?

Maintaining and servicing a cardan joint is important to ensure its optimal performance, reliability, and longevity. Regular maintenance helps prevent premature wear, address potential issues, and prolong the life of the joint. Here’s a detailed explanation of the maintenance and servicing procedures for a cardan joint:

- Visual Inspection: Regularly inspect the cardan joint for any visible signs of damage, wear, or misalignment. Look for cracks, corrosion, loose or missing fasteners, worn bearings, or any abnormalities in the joint components. If any issues are identified, they should be addressed promptly.

- Lubrication: Proper lubrication is essential for the smooth operation of a cardan joint. Follow the manufacturer’s recommendations regarding lubrication type, frequency, quantity, and method. Regularly apply the appropriate lubricant to the designated lubrication points or zerk fittings. Monitor the condition of the lubricant and replenish it as needed to maintain optimal lubrication levels.

- Torque Check: Periodically check the torque of the fasteners that secure the cardan joint and yokes. Over time, vibration and operational stresses can cause fasteners to loosen. Ensure that all fasteners are tightened to the manufacturer’s specified torque values. Be cautious not to overtighten, as it can lead to component damage or failure.

- Alignment Verification: Verify the alignment of the connected shafts that are linked by the cardan joint. Misalignment can cause increased stress and wear on the joint components. Check for any angular misalignment or axial misalignment and make necessary adjustments to minimize misalignment within acceptable tolerances.

- Load and Operating Condition Evaluation: Regularly evaluate the load and operating conditions in which the cardan joint operates. Ensure that the joint is not subjected to excessive loads, speeds, or harsh operating environments beyond its design capabilities. If there are any changes in the operating conditions, consider consulting the manufacturer or an expert to assess the suitability of the cardan joint and make any necessary modifications or replacements.

- Vibration Monitoring: Monitor the vibration levels during operation, as excessive vibration can indicate issues with the cardan joint or the overall system. An increase in vibration may suggest misalignment, worn bearings, or other mechanical problems. If significant vibration is detected, further investigation and corrective actions should be undertaken to address the root cause.

- Periodic Disassembly and Inspection: Depending on the manufacturer’s recommendations and the operating conditions, periodic disassembly and inspection of the cardan joint may be required. This allows for a more thorough assessment of the joint’s condition, including the bearings, seals, and other internal components. Any worn or damaged parts should be replaced with genuine manufacturer-approved replacements.

- Professional Maintenance: In some cases, it may be necessary to engage the services of a professional maintenance technician or a specialized service provider for more comprehensive maintenance or servicing of the cardan joint. They can perform advanced inspections, alignment checks, bearing replacements, or other specialized procedures to ensure the optimal performance of the joint.

It is important to follow the manufacturer’s guidelines and recommendations for maintenance and servicing of the specific cardan joint model. Adhering to proper maintenance practices and promptly addressing any issues that arise will help maximize the service life, reliability, and performance of the cardan joint.

editor by CX 2024-04-12

China manufacturer Truck Parts 22X55 U-Joints Bearing Universal Joints Crucetas Joints De Cardan Cross

Product Description

Product Description

Universal Coupling Cross Bearing Automobile Bearing Universal Joint Bearing

FAQ

1.Q: How do you pack the bearing ?

A: It is ORIGINAL packaging.

It can be done as your specfic demands.

2.Q: Can I get some samples and do you offer the sample free?

A: Yes, sure, we are honored to offer you samples.If we have stock, we can send you free sample.

And you just need to pay freight. If there have no stock, you need to pay sample fee and freight.

3.Q: Does the sample fee can be return back?

A: If you place an order, we can return part of sample fee even all of fee to you.It also depends

on the Quantity of order and the type of sample.

4.Q: What is the MOQ for bearing?

A: Our MOQ is 1 pc.

5.Q: What is the delivery time?

A: According to the order amount or as your request.

6.Q: Can you promise to deliver bearing CHINAMFG 3530 in time?

A: Credit always ranks the top on the list. We will absolutely deliver the goods in 2-4 days after your order is confirmed.

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Aligning: | Non-Aligning Bearing |

|---|---|

| Separated: | Separated |

| Material: | Bearing Steel |

| Samples: |

US$ 5/Piece

1 Piece(Min.Order) | Order Sample |

|---|

| Customization: |

Available

| Customized Request |

|---|

.shipping-cost-tm .tm-status-off{background: none;padding:0;color: #1470cc}

|

Shipping Cost:

Estimated freight per unit. |

about shipping cost and estimated delivery time. |

|---|

| Payment Method: |

|

|---|---|

|

Initial Payment Full Payment |

| Currency: | US$ |

|---|

| Return&refunds: | You can apply for a refund up to 30 days after receipt of the products. |

|---|

How do you calculate the operating angles of a cardan joint?

The operating angles of a cardan joint can be calculated based on the angular misalignment between the input and output shafts. The operating angles are crucial for determining the joint’s performance and ensuring its proper functioning. Here’s a detailed explanation of how to calculate the operating angles of a cardan joint:

- Identify the Shaft Axes: Begin by identifying the axes of the input and output shafts connected by the cardan joint. These axes represent the rotational axes of the shafts.

- Measure the Angular Misalignments: Measure the angular misalignments between the shaft axes. The misalignments are typically measured in terms of angles, such as angular displacement in degrees or radians. There are three types of misalignments to consider:

- Angular Misalignment (α): This refers to the angular difference between the two shaft axes in the horizontal plane (X-Y plane).

- Parallel Misalignment (β): Parallel misalignment represents the offset or displacement between the two shaft axes in the vertical plane (Z-axis).

- Axial Misalignment (γ): Axial misalignment refers to the shift or displacement of one shaft along its axis with respect to the other shaft.

- Calculate the Operating Angles: Once the misalignments are measured, the operating angles can be calculated using trigonometric functions. The operating angles are:

- Operating Angle (θ): The operating angle is the total angular misalignment between the input and output shafts. It is calculated as the square root of the sum of the squares of the individual misalignments:

These calculated operating angles provide valuable information about the misalignment and geometry of the cardan joint. They help in selecting the appropriate joint size, determining the joint’s torque capacity, assessing potential operating issues, and ensuring proper installation and alignment of the joint within the system.

It is important to note that these calculations assume small operating angles and neglect any elastic deformation or non-linearities that may occur in the joint. In cases where larger operating angles or more precise calculations are required, advanced engineering techniques or software tools specific to cardan joint analysis may be employed.

Can cardan joints be used in pumps and compressors?

Yes, cardan joints can be used in pumps and compressors to transmit torque and accommodate misalignments between the driving and driven shafts. They offer several advantages that make them suitable for these applications. Here’s a detailed explanation:

1. Torque Transmission: Pumps and compressors often require the transmission of torque from the driving motor or engine to the rotating shaft that operates the pump or compressor. Cardan joints excel at transmitting torque efficiently, even at significant angles and misalignments. They can handle the high torque loads typically encountered in pump and compressor applications.

2. Misalignment Compensation: Cardan joints are designed to accommodate misalignments between the driving and driven shafts. In pumps and compressors, misalignments can occur due to factors such as thermal expansion, structural deflection, or assembly tolerances. Cardan joints can compensate for these misalignments, ensuring smooth and reliable torque transmission without excessive stress or wear on the connected components.

3. Angular Flexibility: Pumps and compressors often require flexibility in their drivetrain to adapt to different installation configurations or accommodate dynamic movements. Cardan joints provide rotational freedom and allow for angular movement, enabling the pump or compressor to adjust to changing requirements. Their universal joint design allows for smooth rotation and accommodates the required range of motion.

4. Shock and Vibration Absorption: Pumps and compressors can generate significant vibrations and shocks during operation. Cardan joints help absorb these vibrations and shocks, reducing their transmission to the rest of the drivetrain. This feature helps protect other components, such as bearings and seals, from excessive stress and wear, enhancing the overall reliability and lifespan of the pump or compressor.

5. Compact Design: Cardan joints have a relatively compact design, making them suitable for integration into pump and compressor systems where space is often limited. Their compact size allows for efficient packaging within the equipment, optimizing overall design and minimizing footprint. This is especially beneficial in applications where multiple joints are required within a confined space.

6. Durability and Strength: Pumps and compressors operate under demanding conditions, including high pressures, heavy loads, and continuous operation. Cardan joints are often constructed using durable materials such as alloy steels or high-strength alloys, providing the necessary strength and resilience to withstand these conditions. They are designed to handle the demanding loads and forces encountered in pump and compressor applications.

7. Easy Maintenance and Serviceability: Cardan joints are generally low-maintenance components. They require periodic inspection, lubrication, and replacement of worn parts, but their design often allows for easy access and replacement if needed. This facilitates maintenance activities and minimizes downtime in pump and compressor systems.

8. Cost-Effectiveness: Cardan joints offer a cost-effective solution for torque transmission in pump and compressor applications. Their durability, reliability, and long service life contribute to reduced maintenance and replacement costs. Additionally, their ability to accommodate misalignments helps minimize wear on other drivetrain components, further reducing overall maintenance expenses.

When integrating cardan joints into pump and compressor systems, it is important to consider the specific application requirements, operating conditions, and load characteristics. Proper design, selection, and installation practices should be followed to ensure optimal performance and longevity.

Consulting with engineers or experts specializing in drivetrain systems and pump/compressor design can provide valuable insights and guidance on the selection, integration, and maintenance of cardan joints for these applications.

How is a cardan joint different from other types of universal joints?

A cardan joint, also known as a universal joint or U-joint, is a specific type of universal joint design. While there are different variations of universal joints, the cardan joint has distinct characteristics that set it apart from other types. Here’s a detailed explanation of how a cardan joint differs from other universal joints:

1. Design and Structure: The cardan joint consists of two yokes and a cross-shaped member called the cross or spider. The yokes are typically fork-shaped and attached to the shafts, while the cross sits in the center, connecting the yokes. In contrast, other types of universal joints, such as the constant-velocity (CV) joint or Rzeppa joint, have different designs and structures. CV joints often use a combination of bearings and balls to transmit motion and maintain constant velocity, making them suitable for applications requiring smooth rotation without speed fluctuations.

2. Misalignment Compensation: One of the primary functions of a cardan joint is to accommodate misalignment between shafts. It can handle angular misalignment, axial misalignment, or a combination of both. The design of the cardan joint allows for the tilting of the cross as the input and output shafts rotate at different speeds. This tilting action compensates for misalignment and allows the joint to transmit motion. Other types of universal joints, such as the Oldham coupling or Hooke’s joint, have different mechanisms for compensating misalignment. For example, the Oldham coupling uses sliding slots and intermediate disks to accommodate misalignment, while Hooke’s joint uses a combination of rotating links and flexible connections.

3. Operating Range: Cardan joints are commonly used in applications where a wide range of operating angles is required. They can effectively transmit motion and torque at various angles, making them suitable for applications with non-collinear shafts. Other types of universal joints may have specific limitations or operating ranges. For instance, some types of CV joints are designed for constant velocity applications and are optimized for specific operating angles or speed ranges.

4. Applications: Cardan joints find applications in various industries, including automotive, industrial machinery, aerospace, and more. They are commonly used in drivetrain systems, power transmission systems, and applications that require flexibility, misalignment compensation, and reliable motion transmission. Other types of universal joints have their own specific applications. For example, CV joints are commonly used in automotive applications, particularly in front-wheel drive systems, where they provide smooth and constant power transmission while accommodating suspension movements.

5. Limitations: While cardan joints offer flexibility and misalignment compensation, they also have certain limitations. At extreme operating angles, cardan joints can introduce non-uniform motion, increased vibration, backlash, and potential loss of efficiency. Other types of universal joints may have their own limitations and considerations depending on their specific design and application requirements.

In summary, a cardan joint, or universal joint, is a specific type of universal joint design that can accommodate misalignment between shafts and transmit motion at various angles. Its structure, misalignment compensation mechanism, operating range, and applications differentiate it from other types of universal joints. Understanding these distinctions is crucial when selecting the appropriate joint for a specific application.

editor by CX 2024-04-09

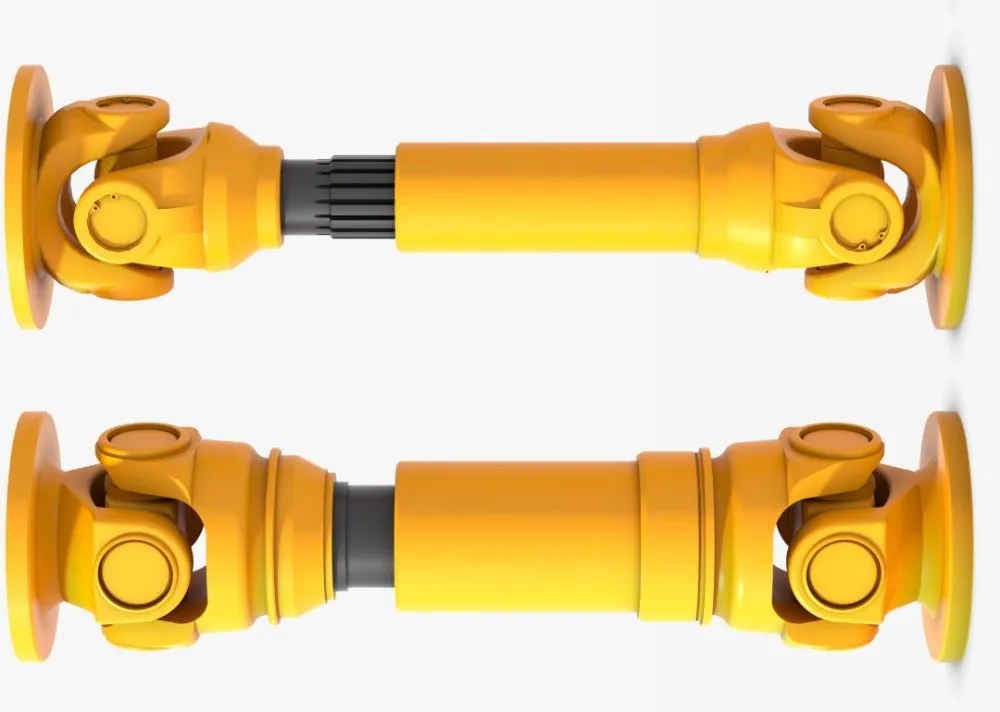

China Professional Truck Auto Parts Cardan Shaft Universal Cross Joint Bearing

Product Description

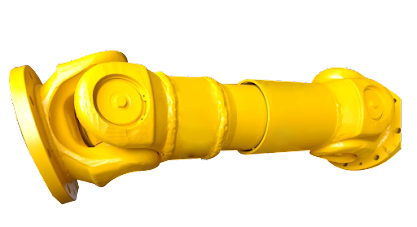

Truck Auto Parts Cardan Shaft Universal Cross Joint

| ZheJiang CHINAMFG Heavy Truck Components Co., Ltd

|

|||

Who we are?

The most professional truck and spare parts manufacturer in China;

The leading truck and spare parts exporter in China;

The most comprehensive truck and spare parts solution provider in China;

The most worry-free and most satisfactory and reputable supplier for you in China.

We can never let you down if you choose us.

FAQ

1)What about your packing?

Generally,our spare parts are packed in anti-rust paper,plastic bag,box,carton or according to customer’s requirements.

2)What about your terms of payment?

L/C, T/T, D/P, Western Union, Paypal Money Gram, Others

3)What is your terms of delivery?

EXW,FOB,CFR,CIF

4)How about your delivery time?

Usually,it will take around 3~7 days after your advance payment,it depends on the items and quantities of your order.

5)What is your sample policy?

We can supply the samples if the samples are in stock,but the customers will pay the sample cost and the delivery cost(or freight collect)

Our Services:

1.All of our products are with professional service.

2.We can offer all kinds of OEM spare parts according to the customer’s requirements.

3. We can offer free consultation of service information .

4.The dominance we kept all along is to provide the customers with genuine spare parts.

5.Standard export packag to protect the parts from long-distance delivery.

6. Professional sales and after sale service team, timely and efficiently to solve your problem.

7.We are willing to privide the High Quality,ReasonablePrice and Perfect Service. /* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Truck Model: | 70mineking |

|---|---|

| Delivery Time: | 3~7 Days |

| MOQ: | 1PCS |

| Payment: | T/T, West Union |

| Transport Package: | Box/Wooden Pallet/Carton |

| Specification: | Standard |

| Samples: |

US$ 14/Piece

1 Piece(Min.Order) | |

|---|

| Customization: |

Available

| Customized Request |

|---|

Can cardan joints be used in heavy-duty machinery and equipment?

Yes, cardan joints can be used in heavy-duty machinery and equipment. Cardan joints, also known as universal joints, are versatile mechanical couplings that transmit torque between misaligned shafts. They offer several advantages that make them suitable for heavy-duty applications. Here’s a detailed explanation of why cardan joints can be used in heavy-duty machinery and equipment:

- Torque Transmission: Cardan joints are capable of transmitting high levels of torque between misaligned shafts. This makes them well-suited for heavy-duty applications that require the transfer of substantial power. The design of the joint allows for smooth torque transmission, even in cases where the shafts are not perfectly aligned.

- Misalignment Compensation: In heavy-duty machinery and equipment, misalignments between shafts can occur due to factors such as thermal expansion, vibration, or structural flexing. Cardan joints excel at compensating for such misalignments. Their flexible design accommodates angular, parallel, and axial misalignments, allowing for reliable operation in challenging industrial environments.

- Durability and Strength: Heavy-duty machinery and equipment often operate under demanding conditions, subjecting components to high loads and harsh environments. Cardan joints are typically constructed from durable materials such as alloy steels, which provide excellent strength and resistance to fatigue and wear. This durability enables them to withstand the heavy loads and prolonged operation associated with heavy-duty applications.

- Compact Design: Cardan joints have a compact design, which is advantageous in heavy-duty machinery and equipment where space constraints may be present. Their compactness allows for efficient installation and integration within the system, making them suitable for applications where minimizing size and weight is important.

- Versatility: Cardan joints are available in various sizes and configurations to accommodate different heavy-duty applications. They can be customized to meet specific torque and speed requirements, making them versatile for use in a wide range of machinery and equipment, including industrial machinery, construction equipment, agricultural machinery, and more.

While cardan joints are generally suitable for heavy-duty applications, it is important to consider certain factors to ensure optimal performance. These factors include proper selection of the joint size and type based on the application requirements, adherence to specified torque and speed limits, regular maintenance to prevent wear and ensure proper lubrication, and consideration of any environmental factors that may affect the joint’s performance.

In summary, cardan joints can indeed be used in heavy-duty machinery and equipment due to their excellent torque transmission capabilities, ability to compensate for misalignments, durability, compact design, and versatility. By considering the specific requirements of the application and following appropriate maintenance practices, cardan joints can provide reliable and efficient operation in heavy-duty industrial settings.

What are the safety considerations when working with cardan joints?

Working with cardan joints requires careful attention to safety to prevent accidents, injuries, and equipment damage. Cardan joints are mechanical components used for torque transmission and misalignment compensation, and they operate under various loads and conditions. Here are important safety considerations to keep in mind when working with cardan joints:

- Proper Training and Knowledge: Ensure that individuals working with cardan joints have proper training and understanding of their operation, installation, and maintenance. Adequate knowledge of safe working practices, procedures, and potential hazards associated with cardan joints is crucial.

- Personal Protective Equipment (PPE): Use appropriate personal protective equipment, such as safety glasses, gloves, and protective clothing, when handling cardan joints. PPE protects against potential hazards like flying debris, sharp edges, or accidental contact with rotating components.

- Lockout/Tagout: Before performing any maintenance or repair work involving cardan joints, follow lockout/tagout procedures to isolate and de-energize the system. This prevents accidental startup or movement of machinery, ensuring the safety of personnel working on or near the cardan joints.

- Secure Mounting and Fastening: Ensure that cardan joints are securely mounted and properly fastened to prevent unexpected movement or dislodgment during operation. Loose joints or fasteners can lead to component failure, sudden movements, or damage to other parts of the system.

- Torque and Load Limits: Adhere to the recommended torque and load limits specified by the manufacturer for the cardan joints. Exceeding these limits can result in premature wear, deformation, or failure of the joints, posing safety risks and compromising the overall system’s functionality.

- Regular Inspection and Maintenance: Implement a regular inspection and maintenance program for the cardan joints. Inspect for signs of wear, damage, or misalignment, and address any issues promptly. Lubricate the joints according to the manufacturer’s recommendations to ensure smooth operation and prevent excessive friction or overheating.

- Safe Handling and Lifting: When handling or lifting cardan joints, use appropriate lifting equipment and techniques. Cardan joints can be heavy, and improper lifting can lead to strain or injuries. Ensure that lifting devices have the capacity to handle the weight of the joints safely.

- Avoid Contact with Rotating Components: Never reach into or make contact with rotating components of a system that incorporates cardan joints while the system is in operation. Keep loose clothing, jewelry, and other items away from moving parts to prevent entanglement or injury.

- Proper Disposal of Used or Damaged Joints: Follow proper disposal procedures for used or damaged cardan joints. Consult local regulations and guidelines for the disposal of mechanical components to minimize environmental impact and ensure compliance with safety and waste management standards.

- Manufacturer’s Guidelines: Always refer to and follow the manufacturer’s guidelines, instructions, and warnings specific to the cardan joints being used. Manufacturers provide important safety information, installation procedures, and maintenance recommendations specific to their products.

By addressing these safety considerations, individuals can mitigate potential risks associated with working with cardan joints, promote a safe working environment, and ensure the reliable and efficient operation of the systems they are integrated into.

How do you choose the right size cardan joint for your application?

Choosing the right size cardan joint for your application is crucial to ensure optimal performance, reliability, and longevity. Several factors need to be considered when selecting the appropriate size of a cardan joint. Here’s a detailed explanation of the key considerations:

- Load Capacity: Determine the maximum load that the cardan joint will need to transmit. Consider both the torque (rotational force) and the axial load (thrust) that will be applied to the joint. The load capacity of the cardan joint should exceed the maximum expected loads in your application to ensure safe and reliable operation.

- Operating Speed: Consider the rotational speed at which the cardan joint will be operating. Higher speeds may require specific design considerations, such as balancing, lubrication, and material selection, to ensure smooth operation and avoid premature wear or failure. Verify that the selected cardan joint is rated for the intended operating speed range.

- Shaft Diameter: Measure the diameter of the input and output shafts that will be connected by the cardan joint. The cardan joint should have yokes and bearings that match the shaft diameter to ensure a proper fit and reliable power transmission. It is essential to consider both shaft diameters when selecting a cardan joint.

- Misalignment Angle: Determine the maximum expected misalignment angle between the input and output shafts. Different types of cardan joints have different capabilities to accommodate misalignment. Consider the angular misalignment and choose a cardan joint that can handle the required range of misalignment angles in your application.

- Environmental Factors: Evaluate the operating environment of the cardan joint. Consider factors such as temperature, humidity, dust, chemicals, and vibration. Choose a cardan joint that is suitable for the specific environmental conditions to ensure proper functioning and longevity.

- Service Life and Maintenance: Consider the expected service life of the cardan joint and the maintenance requirements. Some applications may require frequent maintenance or periodic lubrication of the joint. Evaluate the ease of maintenance and factor it into your selection process.

- Standards and Regulations: Depending on your industry or application, there may be specific standards or regulations that dictate the requirements for cardan joints. Ensure that the selected cardan joint complies with the relevant standards and regulations for your application.

It is advisable to consult with a knowledgeable supplier or engineer specializing in power transmission components to assist you in selecting the right size cardan joint for your specific application. They can consider all the relevant factors and provide guidance to ensure optimal performance and reliability of the cardan joint in your application.

editor by CX 2024-03-14

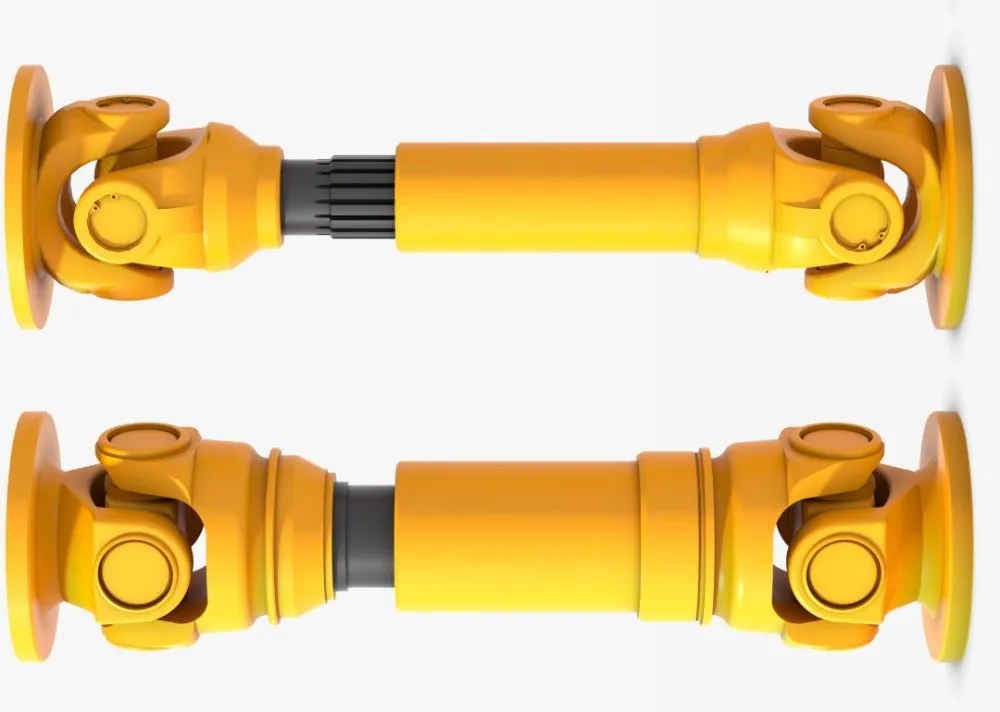

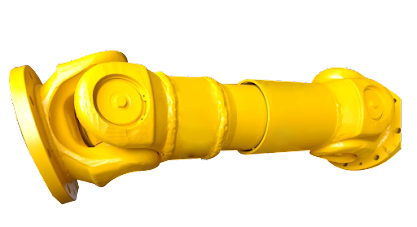

China Custom CNC Turning Machinal Parts Universal Joint Cross Bearing Single Universal Joint Double Universal Cardan Joint

Product Description

Product Description

|

Company Profile

HangZhou Xihu (West Lake) Dis. Machinery Manufacture Co., Ltd., located in HangZhou, “China’s ancient copper capital”, is a “national high-tech enterprise”. At the beginning of its establishment, the company adhering to the “to provide clients with high quality products, to provide timely service” concept, adhere to the “everything for the customer, make customer excellent supplier” for the mission.

Certifications

Q: Where is your company located ?

A: HangZhou ZheJiang .

Q: How could l get a sample?

A: Before we received the first order, please afford the sample cost and express fee. we will return the sample cost back

to you within your first order.

Q: Sample time?

A: Existing items: within 20-60 days.

Q: Whether you could make our brand on your products?

A: Yes. We can print your Logo on both the products and the packages if you can meet our MOQ.

Q: How to guarantee the quality of your products?

A: 1) stict detection during production. 2) Strict completely inspecion on products before shipment and intact product

packaging ensured.

Q: lf my drawings are safe?

A: Yes ,we can CHINAMFG NDA.

/* March 10, 2571 17:59:20 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Standard Or Nonstandard: | Nonstandard |

|---|---|

| Shaft Hole: | 8-24 |

| Torque: | OEM/ODM/Customized |

| Bore Diameter: | OEM/ODM/Customized |

| Speed: | OEM/ODM/Customized |

| Structure: | Flexible |

| Samples: |

US$ 50/Piece

1 Piece(Min.Order) | |

|---|

| Customization: |

Available

| Customized Request |

|---|

Can cardan joints be used in heavy-duty machinery and equipment?

Yes, cardan joints can be used in heavy-duty machinery and equipment. Cardan joints, also known as universal joints, are versatile mechanical couplings that transmit torque between misaligned shafts. They offer several advantages that make them suitable for heavy-duty applications. Here’s a detailed explanation of why cardan joints can be used in heavy-duty machinery and equipment:

- Torque Transmission: Cardan joints are capable of transmitting high levels of torque between misaligned shafts. This makes them well-suited for heavy-duty applications that require the transfer of substantial power. The design of the joint allows for smooth torque transmission, even in cases where the shafts are not perfectly aligned.

- Misalignment Compensation: In heavy-duty machinery and equipment, misalignments between shafts can occur due to factors such as thermal expansion, vibration, or structural flexing. Cardan joints excel at compensating for such misalignments. Their flexible design accommodates angular, parallel, and axial misalignments, allowing for reliable operation in challenging industrial environments.

- Durability and Strength: Heavy-duty machinery and equipment often operate under demanding conditions, subjecting components to high loads and harsh environments. Cardan joints are typically constructed from durable materials such as alloy steels, which provide excellent strength and resistance to fatigue and wear. This durability enables them to withstand the heavy loads and prolonged operation associated with heavy-duty applications.

- Compact Design: Cardan joints have a compact design, which is advantageous in heavy-duty machinery and equipment where space constraints may be present. Their compactness allows for efficient installation and integration within the system, making them suitable for applications where minimizing size and weight is important.

- Versatility: Cardan joints are available in various sizes and configurations to accommodate different heavy-duty applications. They can be customized to meet specific torque and speed requirements, making them versatile for use in a wide range of machinery and equipment, including industrial machinery, construction equipment, agricultural machinery, and more.

While cardan joints are generally suitable for heavy-duty applications, it is important to consider certain factors to ensure optimal performance. These factors include proper selection of the joint size and type based on the application requirements, adherence to specified torque and speed limits, regular maintenance to prevent wear and ensure proper lubrication, and consideration of any environmental factors that may affect the joint’s performance.

In summary, cardan joints can indeed be used in heavy-duty machinery and equipment due to their excellent torque transmission capabilities, ability to compensate for misalignments, durability, compact design, and versatility. By considering the specific requirements of the application and following appropriate maintenance practices, cardan joints can provide reliable and efficient operation in heavy-duty industrial settings.

Can cardan joints be used in conveyor systems?

Yes, cardan joints can be used in conveyor systems, and they offer several advantages in certain applications. Cardan joints, also known as universal joints, are versatile mechanical couplings that provide flexibility in transmitting torque and accommodating misalignments between rotating shafts. Here’s a detailed explanation of the use of cardan joints in conveyor systems:

Conveyor systems are widely used in various industries for the efficient movement of bulk materials, goods, or components. These systems consist of multiple components, including conveyor belts, pulleys, rollers, and drive systems, that work together to transport materials from one location to another.

Cardan joints can be integrated into conveyor systems to enable torque transmission and accommodate misalignments in certain parts of the system. Here are some key considerations and advantages of using cardan joints in conveyor systems:

- Misalignment Compensation: Conveyor systems often require flexibility to accommodate misalignments between different components, such as pulleys and drive shafts. Cardan joints provide a flexible coupling solution that can handle angular, parallel, and axial misalignments, allowing smooth operation and minimizing stress on the system.

- Torque Transmission: Cardan joints are designed to transmit torque between shafts that are not aligned. In conveyor systems, they can be used to connect the drive shaft to the pulleys or rollers, allowing torque to be efficiently transferred throughout the system. This enables the movement of the conveyor belt and facilitates the transportation of materials along the desired path.

- Compact Design: Cardan joints offer a compact and space-saving design, making them suitable for conveyor systems with limited space constraints. Their small size allows for efficient integration into the system without compromising its overall footprint.

- High Load Capacity: Conveyor systems often handle significant loads, and the components must be capable of withstanding these loads. Cardan joints are designed to handle high torque and can transmit substantial loads, making them suitable for conveyor systems that require robust and reliable torque transmission.

- Variable Speed and Direction: Cardan joints provide the ability to transmit torque at various angles, allowing conveyor systems to operate at different speeds and change direction if needed. This flexibility allows for versatility in conveyor system design and adaptability to different material handling requirements.

- Reduced Vibrations and Noise: Cardan joints can help dampen vibrations and reduce noise levels in conveyor systems. The flexible coupling nature of the joint absorbs and dampens vibrations caused by the operation of the system, resulting in smoother and quieter performance.

- Application-Specific Considerations: The use of cardan joints in conveyor systems requires careful consideration of specific application requirements, such as the type of material being transported, system layout, operating conditions, and load characteristics. Proper selection of the cardan joint size, materials, lubrication, and maintenance practices is essential to ensure optimal performance and reliability.

It is worth noting that while cardan joints can offer advantages in certain conveyor system applications, other types of couplings or drive systems may be more suitable depending on the specific requirements and constraints of the system. Consulting with engineers and industry experts can help determine the most appropriate coupling solution for a given conveyor system.

How do you maintain and service a cardan joint?

Maintaining and servicing a cardan joint is important to ensure its optimal performance, reliability, and longevity. Regular maintenance helps prevent premature wear, address potential issues, and prolong the life of the joint. Here’s a detailed explanation of the maintenance and servicing procedures for a cardan joint:

- Visual Inspection: Regularly inspect the cardan joint for any visible signs of damage, wear, or misalignment. Look for cracks, corrosion, loose or missing fasteners, worn bearings, or any abnormalities in the joint components. If any issues are identified, they should be addressed promptly.

- Lubrication: Proper lubrication is essential for the smooth operation of a cardan joint. Follow the manufacturer’s recommendations regarding lubrication type, frequency, quantity, and method. Regularly apply the appropriate lubricant to the designated lubrication points or zerk fittings. Monitor the condition of the lubricant and replenish it as needed to maintain optimal lubrication levels.

- Torque Check: Periodically check the torque of the fasteners that secure the cardan joint and yokes. Over time, vibration and operational stresses can cause fasteners to loosen. Ensure that all fasteners are tightened to the manufacturer’s specified torque values. Be cautious not to overtighten, as it can lead to component damage or failure.

- Alignment Verification: Verify the alignment of the connected shafts that are linked by the cardan joint. Misalignment can cause increased stress and wear on the joint components. Check for any angular misalignment or axial misalignment and make necessary adjustments to minimize misalignment within acceptable tolerances.

- Load and Operating Condition Evaluation: Regularly evaluate the load and operating conditions in which the cardan joint operates. Ensure that the joint is not subjected to excessive loads, speeds, or harsh operating environments beyond its design capabilities. If there are any changes in the operating conditions, consider consulting the manufacturer or an expert to assess the suitability of the cardan joint and make any necessary modifications or replacements.

- Vibration Monitoring: Monitor the vibration levels during operation, as excessive vibration can indicate issues with the cardan joint or the overall system. An increase in vibration may suggest misalignment, worn bearings, or other mechanical problems. If significant vibration is detected, further investigation and corrective actions should be undertaken to address the root cause.

- Periodic Disassembly and Inspection: Depending on the manufacturer’s recommendations and the operating conditions, periodic disassembly and inspection of the cardan joint may be required. This allows for a more thorough assessment of the joint’s condition, including the bearings, seals, and other internal components. Any worn or damaged parts should be replaced with genuine manufacturer-approved replacements.

- Professional Maintenance: In some cases, it may be necessary to engage the services of a professional maintenance technician or a specialized service provider for more comprehensive maintenance or servicing of the cardan joint. They can perform advanced inspections, alignment checks, bearing replacements, or other specialized procedures to ensure the optimal performance of the joint.

It is important to follow the manufacturer’s guidelines and recommendations for maintenance and servicing of the specific cardan joint model. Adhering to proper maintenance practices and promptly addressing any issues that arise will help maximize the service life, reliability, and performance of the cardan joint.

editor by CX 2024-02-14

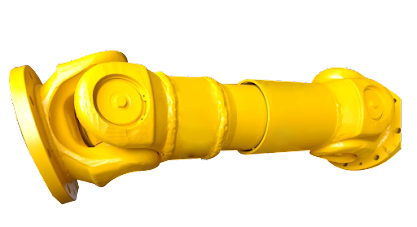

China Good quality Made in China Splitting Machine Spare Parts Bearing Precision Coupling Cardan Joint

Product Description

Product Description

|

Company Profile

HangZhou Xihu (West Lake) Dis. Machinery Manufacture Co., Ltd., located in HangZhou, “China’s ancient copper capital”, is a “national high-tech enterprise”. At the beginning of its establishment, the company adhering to the “to provide clients with high quality products, to provide timely service” concept, adhere to the “everything for the customer, make customer excellent supplier” for the mission.

Certifications

Q: Where is your company located ?

A: HangZhou ZheJiang .

Q: How could l get a sample?

A: Before we received the first order, please afford the sample cost and express fee. we will return the sample cost back

to you within your first order.

Q: Sample time?

A: Existing items: within 20-60 days.

Q: Whether you could make our brand on your products?

A: Yes. We can print your Logo on both the products and the packages if you can meet our MOQ.

Q: How to guarantee the quality of your products?

A: 1) stict detection during production. 2) Strict completely inspecion on products before shipment and intact product

packaging ensured.

Q: lf my drawings are safe?

A: Yes ,we can CHINAMFG NDA.

/* March 10, 2571 17:59:20 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Standard Or Nonstandard: | Nonstandard |

|---|---|

| Shaft Hole: | 8-24 |

| Structure: | Flexible |

| Material: | Stainless Steel |

| Type: | Universal Coupling |

| Shape: | Non-Standard |

| Samples: |

US$ 50/Piece

1 Piece(Min.Order) | |

|---|

| Customization: |

Available

| Customized Request |

|---|

What are the potential limitations or drawbacks of using cardan joints?

While cardan joints offer numerous advantages in transmitting rotational motion between misaligned shafts, they also have certain limitations and drawbacks to consider. Here are some potential limitations associated with the use of cardan joints:

- Angular Limitations: Cardan joints have limited angularity or operating angles. They are designed to operate within specific angular ranges, and exceeding these angles can cause accelerated wear, increased vibration, and potential joint failure. Extreme operating angles can lead to binding, decreased efficiency, and reduced power transmission capacity. In applications where large operating angles are required, alternative flexible coupling mechanisms or constant velocity joints may be more suitable.

- Backlash and Torsional Stiffness: Cardan joints inherently exhibit some degree of backlash, which is the clearance or free play between the mating components. This can result in a slight delay in power transmission and can affect the precision of motion in certain applications. Additionally, cardan joints may have higher torsional stiffness compared to other coupling mechanisms, which can transmit higher vibrations and shocks to the connected components.

- Maintenance Requirements: Cardan joints require regular maintenance to ensure proper lubrication, alignment, and performance. The lubricant needs to be regularly replenished or replaced, and the joint should be inspected for wear, misalignment, or other issues. Failure to perform adequate maintenance can result in premature wear, reduced efficiency, and potential joint failure. Maintenance procedures may require specialized tools and expertise.

- Space and Weight: Cardan joints can occupy a significant amount of space due to their design and the need for perpendicular shafts. In applications with limited space constraints, finding suitable locations for cardan joints can be challenging. Additionally, the weight of cardan joints, especially in heavy-duty applications, can add to the overall weight of the system, which may have implications for fuel efficiency, payload capacity, or overall performance.

- Cost: Cardan joints, particularly high-quality and precision-engineered ones, can be relatively expensive compared to other coupling mechanisms. The complex design, manufacturing tolerances, and specialized materials involved contribute to their higher cost. In cost-sensitive applications, alternative coupling solutions may be considered if the angular limitations and other drawbacks of cardan joints are not critical.

- High-Speed Limitations: At high rotational speeds, cardan joints can experience increased vibration, imbalance, and potential for fatigue failure. The rotating components of the joint can generate centrifugal forces that impact the balance and stability of the system. In high-speed applications, careful design considerations, including balancing and vibration analysis, may be necessary to mitigate these issues.

It is important to evaluate the specific application requirements, operating conditions, and limitations when considering the use of cardan joints. While they offer versatility and flexibility in many scenarios, alternative coupling mechanisms may be more suitable in cases where the limitations and drawbacks of cardan joints pose significant challenges.

How do you ensure reliable and consistent performance in a cardan joint?

Ensuring reliable and consistent performance in a cardan joint requires attention to various factors, including proper design, maintenance, and operating practices. By following best practices and considering key considerations, the reliability and performance of a cardan joint can be optimized. Here’s a detailed explanation:

1. Proper Design and Selection: The first step is to ensure the cardan joint is properly designed and selected for the intended application. Consider factors such as load requirements, operating conditions (including speed and temperature), misalignment angles, and torque transmission needs. Choose a cardan joint that is appropriately sized and rated to handle the specific demands of the application.

2. Material Selection: Selecting the appropriate materials for the cardan joint is crucial for long-term performance. Consider factors such as strength, fatigue resistance, and corrosion resistance. The materials should be compatible with the operating environment and any potential exposure to chemicals, moisture, or extreme temperatures.

3. Regular Inspection and Maintenance: Implement a regular inspection and maintenance schedule to identify any signs of wear, damage, or misalignment. This includes checking for excessive play, backlash, or abnormal vibrations. Regularly lubricate the joint as per the manufacturer’s recommendations and ensure that seals are intact to prevent contamination.

4. Alignment and Installation: Proper alignment during installation is critical for optimal performance. Ensure that the joint is aligned correctly with the connected shafts to minimize misalignment and reduce stress on the joint. Precise alignment helps to minimize wear, maximize torque transmission efficiency, and extend the life of the joint.

5. Load Considerations: Be mindful of the loads applied to the cardan joint. Avoid exceeding the recommended load limits and consider factors such as shock loads, torsional forces, and variations in load during operation. Excessive loads can lead to premature wear, fatigue, and failure of the joint.

6. Temperature Management: Maintain suitable operating temperatures for the cardan joint. Excessive heat or extreme temperature fluctuations can affect the performance and longevity of the joint. Ensure proper cooling or lubrication mechanisms are in place if operating conditions generate significant heat.

7. Training and Operator Awareness: Provide proper training to operators and maintenance personnel regarding the cardan joint’s operation, maintenance requirements, and potential failure modes. Encourage regular inspection and reporting of any abnormalities to address issues promptly.

8. Consider Additional Measures: Depending on the application and specific requirements, additional measures can be implemented to enhance performance and reliability. This may include incorporating backlash compensation systems, using precision-aligned cardan joints, or integrating monitoring systems to detect early signs of wear or misalignment.

By considering these factors and implementing best practices, reliable and consistent performance can be achieved in a cardan joint. Regular monitoring, maintenance, and prompt corrective actions are essential to ensure the joint operates optimally and delivers the expected performance throughout its service life.

How do you maintain and service a cardan joint?

Maintaining and servicing a cardan joint is important to ensure its optimal performance, reliability, and longevity. Regular maintenance helps prevent premature wear, address potential issues, and prolong the life of the joint. Here’s a detailed explanation of the maintenance and servicing procedures for a cardan joint:

- Visual Inspection: Regularly inspect the cardan joint for any visible signs of damage, wear, or misalignment. Look for cracks, corrosion, loose or missing fasteners, worn bearings, or any abnormalities in the joint components. If any issues are identified, they should be addressed promptly.

- Lubrication: Proper lubrication is essential for the smooth operation of a cardan joint. Follow the manufacturer’s recommendations regarding lubrication type, frequency, quantity, and method. Regularly apply the appropriate lubricant to the designated lubrication points or zerk fittings. Monitor the condition of the lubricant and replenish it as needed to maintain optimal lubrication levels.

- Torque Check: Periodically check the torque of the fasteners that secure the cardan joint and yokes. Over time, vibration and operational stresses can cause fasteners to loosen. Ensure that all fasteners are tightened to the manufacturer’s specified torque values. Be cautious not to overtighten, as it can lead to component damage or failure.

- Alignment Verification: Verify the alignment of the connected shafts that are linked by the cardan joint. Misalignment can cause increased stress and wear on the joint components. Check for any angular misalignment or axial misalignment and make necessary adjustments to minimize misalignment within acceptable tolerances.

- Load and Operating Condition Evaluation: Regularly evaluate the load and operating conditions in which the cardan joint operates. Ensure that the joint is not subjected to excessive loads, speeds, or harsh operating environments beyond its design capabilities. If there are any changes in the operating conditions, consider consulting the manufacturer or an expert to assess the suitability of the cardan joint and make any necessary modifications or replacements.

- Vibration Monitoring: Monitor the vibration levels during operation, as excessive vibration can indicate issues with the cardan joint or the overall system. An increase in vibration may suggest misalignment, worn bearings, or other mechanical problems. If significant vibration is detected, further investigation and corrective actions should be undertaken to address the root cause.

- Periodic Disassembly and Inspection: Depending on the manufacturer’s recommendations and the operating conditions, periodic disassembly and inspection of the cardan joint may be required. This allows for a more thorough assessment of the joint’s condition, including the bearings, seals, and other internal components. Any worn or damaged parts should be replaced with genuine manufacturer-approved replacements.

- Professional Maintenance: In some cases, it may be necessary to engage the services of a professional maintenance technician or a specialized service provider for more comprehensive maintenance or servicing of the cardan joint. They can perform advanced inspections, alignment checks, bearing replacements, or other specialized procedures to ensure the optimal performance of the joint.

It is important to follow the manufacturer’s guidelines and recommendations for maintenance and servicing of the specific cardan joint model. Adhering to proper maintenance practices and promptly addressing any issues that arise will help maximize the service life, reliability, and performance of the cardan joint.

editor by CX 2023-12-27

China factory Truck Parts 22X55 U-Joints Bearing Universal Joints Crucetas Joints De Cardan Cross

Product Description

Product Description

Universal Coupling Cross Bearing Automobile Bearing Universal Joint Bearing

FAQ

1.Q: How do you pack the bearing ?

A: It is ORIGINAL packaging.

It can be done as your specfic demands.

2.Q: Can I get some samples and do you offer the sample free?

A: Yes, sure, we are honored to offer you samples.If we have stock, we can send you free sample.

And you just need to pay freight. If there have no stock, you need to pay sample fee and freight.

3.Q: Does the sample fee can be return back?

A: If you place an order, we can return part of sample fee even all of fee to you.It also depends

on the Quantity of order and the type of sample.

4.Q: What is the MOQ for bearing?

A: Our MOQ is 1 pc.

5.Q: What is the delivery time?

A: According to the order amount or as your request.

6.Q: Can you promise to deliver bearing CHINAMFG 3530 in time?

A: Credit always ranks the top on the list. We will absolutely deliver the goods in 2-4 days after your order is confirmed.

/* March 10, 2571 17:59:20 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Aligning: | Non-Aligning Bearing |

|---|---|

| Separated: | Separated |

| Material: | Bearing Steel |

| Samples: |

US$ 5/Piece

1 Piece(Min.Order) | Order Sample |

|---|

| Customization: |

Available

| Customized Request |

|---|

.shipping-cost-tm .tm-status-off{background: none;padding:0;color: #1470cc}

|

Shipping Cost:

Estimated freight per unit. |

about shipping cost and estimated delivery time. |

|---|

| Payment Method: |

|

|---|---|

|

Initial Payment Full Payment |

| Currency: | US$ |

|---|

| Return&refunds: | You can apply for a refund up to 30 days after receipt of the products. |

|---|

What is the role of needle bearings in a cardan joint?

Needle bearings play a crucial role in the smooth operation and performance of a cardan joint. They are commonly used as a type of rolling element bearing within the joint’s design. The primary role of needle bearings in a cardan joint is to provide support, reduce friction, and facilitate the transmission of torque between the joint’s components. Here’s a detailed explanation of the role of needle bearings in a cardan joint: