Product Description

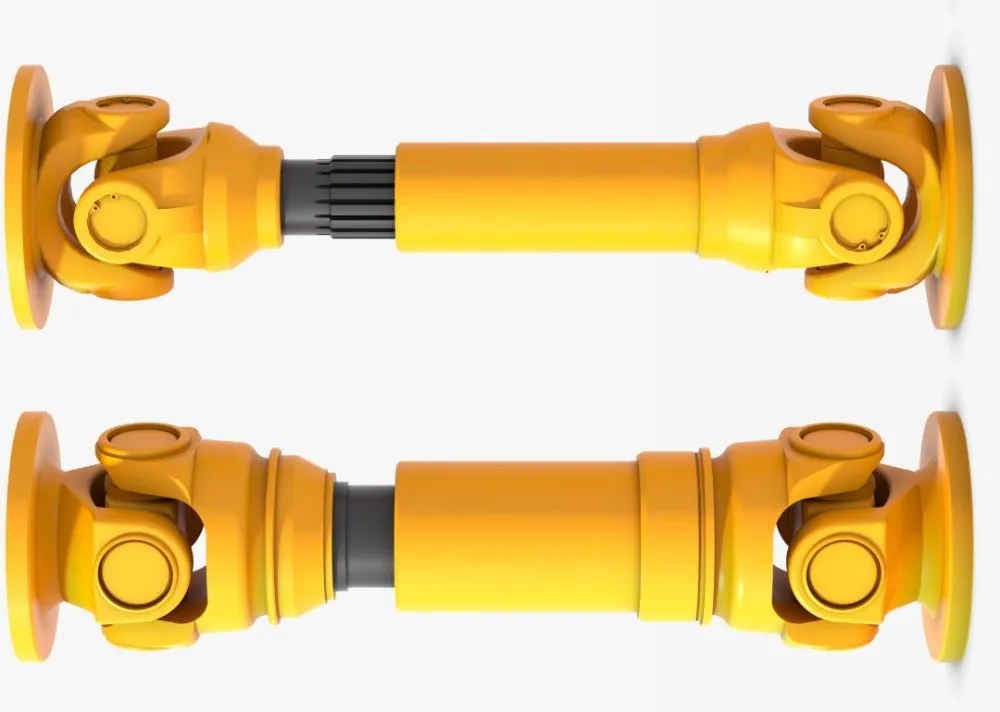

| Product Name | Stainless Steel Universal Joint Single Double U Joint Cardan |

| Material | Stainless Steel,Alloy Steel,Steel C45 |

| Model NO. | PR/PB/NB/CN |

| Surface Treatment | Black Oxide |

| Operating Angle | 45 Degree |

| Manufacturing Process | CNC Maching |

Features

1.Application to all kinds of general mechanical situation, maximum rotate speed may reach1000~1500r/min.

Our Universal Joint widely used in multiaxle drilling machine ,construction machine,packaging machine,automobile.parking facility and paper machine,medical machine,farm machine

2.Have single -jointed type and bimodal type

3.Each point of the largest rotation angle can be 45°

4.Needle roller bearing,maintenance-free

5.The hole on the finshed product tolerance is H7 according to spline , hexagonal and square hole are available as long as you request.

Advantages

• Many sizes available

• Max. angle 45 degree

• Max. speed 1000 rpm

• Available in various materials

• All subcomponents very precisely machined from bar: No cheap castings or powdered metal parts, resulting in better overall and more consistent performance

• Several subtle design innovations that optimize performance and reduce cost

• Could manufacture products according to your drawing

Variations offered

• Materials for midsection(Cube and Pin): 20Cr,40Cr

• Materials for hub: 40Cr,45#steel

• Materials for spline: 45#steel

Other material Carbon steel 20Crmo and 40Crmo, and Stainless steel.Quick-Change universal joint(Nature color )

Our Service

1) Competitive price and good quality.

2) Used for transmission systems.

3) Excellent performance, long using life.

4) Could be developed according to your drawings or data sheet.

5) Pakaging:follow the customers’ requirements or as our usual package.

6) Brand name: per every customer’s requirement.

7) Flexible minimum order quantity.

8) Sample can be supplied.

| Packing&Shipping | |

| Package | Standard suitable package / Pallet or container. Polybag inside export carton outside, blister and Tape and reel package available. If customers have specific requirements for the packaging, we will gladly accommodate. |

| Shipping |

10-20working days ofter payment receipt comfirmed (based on actual quantity). Professional goods shipping forward. |

About MIGHTY

ZheJiang Mighty Machinery Co., Ltd. specializes in manufacturing Mechanical Power Transmission Products.We Mighty is the division/branch of SCMC Group, which is a wholly state-owned company, established in 1980.

About Mighty:

-3 manufacturing factories, we have 5 technical staff, our FTY have strong capacity for design and process design, and more than 70 workers and double shift eveyday.

-Large quality of various material purchase and stock in warhouse which ensure the low cost for the material and production in time.

-Strick quality control are apply in the whole production.

we have incoming inspection,process inspection and final production inspection which can ensure the perfect of the goods quality.

-14 years of machining experience. Long time cooperate with the Global Buyer, make us easy to understand the csutomer and handle the export. MIGHTY’s products are mainly exported to Europe, America and the Middle East market. With the top-ranking management, professional technical support and abundant export experience, MIGHTY has established lasting and stable business partnership with many world famous companies and has got good reputation from CHINAMFG customers in international sales.

FAQ

Q: Are you trading company or manufacturer?

A: We are factory.

Q: How long is your delivery time?

A: Generally it is 5-10 days if the goods are in stock. or it is 15-20 days if the goods are not in stock, it is according to quantity.

Q: Do you provide samples ? is it free or extra ?

A: Yes, we could offer the sample for free charge but do not pay the cost of freight.

Q: What is your terms of payment ?

A: Payment=1000USD, 30% T/T in advance ,balance before shippment.

We warmly welcome friends from domestic and abroad come to us for business negotiation and cooperation for mutual benefit. To supply customers excellent quality products with good price and punctual delivery time is our responsibility.

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| After-sales Service: | Technical Support |

|---|---|

| Warranty: | 1 Year |

| Condition: | New |

| Color: | Customized |

| Certification: | CE, DIN, ISO |

| Structure: | Single or Double |

| Samples: |

US$ 0/Piece

1 Piece(Min.Order) | |

|---|

| Customization: |

Available

| Customized Request |

|---|

Are cardan joints suitable for both high-torque and high-speed applications?

Cardan joints can be used in a variety of applications, but their suitability for high-torque and high-speed applications depends on several factors. Here’s a detailed explanation of the considerations regarding the use of cardan joints in such scenarios:

1. High-Torque Applications: Cardan joints are generally well-suited for high-torque applications. The design of the joint allows for the transmission of significant torque between misaligned shafts. However, it is important to consider the specific torque requirements and operating conditions. Factors such as the size and type of the joint, the material used, and the application’s torque demands should be taken into account. In extremely high-torque applications, alternative coupling mechanisms such as gear couplings or universal joints may be more appropriate.

2. High-Speed Applications: While cardan joints can operate at relatively high speeds, there are some limitations to consider. At high rotational speeds, cardan joints can experience increased vibration, imbalance, and potential for fatigue failure. The rotating components of the joint can generate centrifugal forces, which can impact the balance and stability of the system. To mitigate these issues, careful design considerations, including balancing and vibration analysis, may be necessary. In some cases, alternative coupling mechanisms like flexible couplings or constant velocity joints may be better suited for high-speed applications.

3. Balancing and Vibration Control: Balancing the rotating components, such as the driveshaft and the joint itself, is essential for minimizing vibration issues in high-torque and high-speed applications. Imbalance can lead to increased vibrations, reduced efficiency, and potential damage to the joint and other system components. Proper balancing techniques, including dynamic balancing during manufacturing or precision balancing during installation, can help achieve smoother operation and minimize vibration problems.

4. Material Selection: The material used in the construction of the cardan joint plays a crucial role in its suitability for high-torque and high-speed applications. High-strength materials, such as alloy steels, are often preferred for their ability to handle increased torque loads. Additionally, materials with good fatigue resistance and high-speed capabilities can help ensure the durability and reliability of the joint in demanding applications.

5. Application-Specific Factors: The suitability of cardan joints for high-torque and high-speed applications also depends on the specific requirements and operating conditions of the application. Factors such as load characteristics, duty cycles, temperature, and environmental conditions should be considered. It is important to consult with the manufacturer or engineering experts to determine the appropriate size, type, and configuration of the cardan joint for a particular high-torque or high-speed application.

In summary, cardan joints can be suitable for both high-torque and high-speed applications, but careful consideration of factors such as torque requirements, speed limitations, balancing, material selection, and application-specific conditions is necessary. Evaluating these factors and consulting with experts can help determine the optimal coupling solution for a given high-torque or high-speed application.

What are the safety considerations when working with cardan joints?

Working with cardan joints requires careful attention to safety to prevent accidents, injuries, and equipment damage. Cardan joints are mechanical components used for torque transmission and misalignment compensation, and they operate under various loads and conditions. Here are important safety considerations to keep in mind when working with cardan joints:

- Proper Training and Knowledge: Ensure that individuals working with cardan joints have proper training and understanding of their operation, installation, and maintenance. Adequate knowledge of safe working practices, procedures, and potential hazards associated with cardan joints is crucial.

- Personal Protective Equipment (PPE): Use appropriate personal protective equipment, such as safety glasses, gloves, and protective clothing, when handling cardan joints. PPE protects against potential hazards like flying debris, sharp edges, or accidental contact with rotating components.

- Lockout/Tagout: Before performing any maintenance or repair work involving cardan joints, follow lockout/tagout procedures to isolate and de-energize the system. This prevents accidental startup or movement of machinery, ensuring the safety of personnel working on or near the cardan joints.

- Secure Mounting and Fastening: Ensure that cardan joints are securely mounted and properly fastened to prevent unexpected movement or dislodgment during operation. Loose joints or fasteners can lead to component failure, sudden movements, or damage to other parts of the system.

- Torque and Load Limits: Adhere to the recommended torque and load limits specified by the manufacturer for the cardan joints. Exceeding these limits can result in premature wear, deformation, or failure of the joints, posing safety risks and compromising the overall system’s functionality.

- Regular Inspection and Maintenance: Implement a regular inspection and maintenance program for the cardan joints. Inspect for signs of wear, damage, or misalignment, and address any issues promptly. Lubricate the joints according to the manufacturer’s recommendations to ensure smooth operation and prevent excessive friction or overheating.

- Safe Handling and Lifting: When handling or lifting cardan joints, use appropriate lifting equipment and techniques. Cardan joints can be heavy, and improper lifting can lead to strain or injuries. Ensure that lifting devices have the capacity to handle the weight of the joints safely.

- Avoid Contact with Rotating Components: Never reach into or make contact with rotating components of a system that incorporates cardan joints while the system is in operation. Keep loose clothing, jewelry, and other items away from moving parts to prevent entanglement or injury.

- Proper Disposal of Used or Damaged Joints: Follow proper disposal procedures for used or damaged cardan joints. Consult local regulations and guidelines for the disposal of mechanical components to minimize environmental impact and ensure compliance with safety and waste management standards.

- Manufacturer’s Guidelines: Always refer to and follow the manufacturer’s guidelines, instructions, and warnings specific to the cardan joints being used. Manufacturers provide important safety information, installation procedures, and maintenance recommendations specific to their products.

By addressing these safety considerations, individuals can mitigate potential risks associated with working with cardan joints, promote a safe working environment, and ensure the reliable and efficient operation of the systems they are integrated into.

Are there different types of cardan joints available?

Yes, there are different types of cardan joints available to suit various applications and requirements. The design and configuration of a cardan joint can vary based on factors such as load capacity, torque transmission, operating conditions, and installation constraints. Here’s a detailed explanation of some commonly used types of cardan joints:

- Single Universal Joint: The single universal joint is the most basic and commonly used type of cardan joint. It consists of two yokes connected by a cross, forming a single joint. This type of cardan joint allows for angular misalignment between the input and output shafts. It is often used in applications where misalignment angles are relatively small, and flexibility is required.

- Double Cardan Joint: The double cardan joint, also known as a constant velocity joint (CV joint), is an enhanced version of the single universal joint. It consists of two single universal joints connected by an intermediate shaft. This configuration helps to cancel out the velocity fluctuations and torque variations that can occur with a single joint. Double cardan joints are commonly used in applications where smooth and constant power transmission is required, such as in front-wheel drive vehicles.

- Tractor Joint: A tractor joint is a specialized type of cardan joint used in agricultural machinery, particularly in power take-off (PTO) systems. It consists of three yokes connected by two crosses. The tractor joint allows for higher torque transmission and can accommodate larger misalignment angles. It is designed to handle the demanding conditions and heavy loads often encountered in agricultural applications.

- Ball-and-Socket Joint: The ball-and-socket joint, also known as a Hooke’s joint, is another variant of the cardan joint. It consists of a cross with a spherical ball at each end, which fits into a corresponding socket in the yokes. The ball-and-socket joint provides greater flexibility and can accommodate larger angles of misalignment. It is commonly used in applications where significant angular movement is required, such as steering systems in vehicles.

- Flexible Coupling: While not strictly a cardan joint, flexible couplings serve a similar purpose in accommodating misalignment. Flexible couplings are often used in applications where the misalignment is minimal and torque transmission is a primary concern. They utilize elastomeric or flexible elements to provide flexibility and compensate for small misalignments between shafts.

These are some of the commonly used types of cardan joints. Each type offers specific advantages and is suitable for different applications based on factors such as misalignment requirements, torque transmission, and operating conditions. The selection of the appropriate cardan joint type depends on the specific needs of the application and the desired performance characteristics.

editor by CX 2024-05-15